Manufacturing control is a vital aspect of any manufacturing business. It involves monitoring and regulating the production process to ensure that output is consistent, of high quality and meets the required standards. Much like baking cookies variables such as time, temperature, and ingredients can spoil batches if not calibrated properly in manufacturing settings.

Creating an effective manufacturing control plan can be a daunting task, but it's essential for the success of any business. A baseline understanding of the production process is necessary to determine how best to regulate it. The goal is to ensure that each batch meets the same standards so that customers receive a consistent product every time. Without proper manufacturing control, companies risk delivering products that don't live up to expectations, leading to unhappy customers and lost revenue.

In this article, we will explore various strategies for achieving successive output and discuss how businesses can implement an effective manufacturing control plan to optimize their output. We'll also provide insights into common pitfalls to avoid as you develop your strategy so that you can achieve optimal results and improve your bottom line with efficient processes that deliver consistent results no matter what challenges may arise along the way.

For another approach, see: Manufacturing Process Automation

Unveiling the Basics of Manufacturing Control

Manufacturing control is a process used to manage manufacturing processes, monitor control systems, and optimize production. The main goal of manufacturing process control aims to produce products that exceed quality standards while minimizing waste and maximizing efficiency. Manufacturers rely on a variety of software components, sensors, controllers, and actuators to collect data and monitor the production process.

By using these technologies, manufacturers can identify trends in their production process and take action to improve quality. For example, if a manufacturer notices that a certain machine is producing products with more defects than usual, they can use the data collected by sensors to identify the problem and make changes to fix it.

One of the primary benefits of manufacturing control is its ability to improve product quality by identifying problems early on in the production process. By using sensors and other technology to collect data about each step in the production process, manufacturers can quickly identify any issues that arise and take steps to correct them before they become bigger problems. Ultimately, this leads to higher-quality products that meet or exceed customer expectations.

For more insights, see: Barcode Inventory Control

Why PPE Manufacturing Matters: The Key to Staying Safe

PPE manufacturing equipment is a crucial element of staying safe in hazardous working conditions. Without proper personal protective equipment, workers are susceptible to serious injury or illness. This is why PPE manufacturing matters - it provides the necessary gear for employees to protect themselves while on the job.

Production lines that manufacture PPE must be carefully controlled and monitored to ensure top-quality products. This is where manufacturing software comes into play. It helps businesses track inventory, manage orders, and improve production efficiency. By implementing manufacturing software, companies can streamline their processes and improve their bottom line.

As a business tip, investing in PPE manufacturing is not only beneficial for employee safety but also for the company's overall success. By producing high-quality products and ensuring worker safety, companies can build a positive reputation within their industry and attract new customers. In today's world, where health and safety concerns are at an all-time high, prioritizing PPE manufacturing should be a top priority for any business looking to succeed.

Recommended read: Agricultural Equipment Manufacturers

Deliver your projectson time and under budget

"Start planning" is the key to delivering your manufacturing projects on time and under budget. This means creating a detailed project plan that outlines all necessary tasks, timelines, and resources needed to complete the project. By starting with a solid plan and regularly checking progress against it, you can identify potential delays or cost overruns early on and adjust accordingly. Additionally, effective communication and collaboration with all stakeholders involved in the project can help ensure everyone is aligned on priorities and expectations, reducing the likelihood of misunderstandings or surprises down the line.

Broaden your view: Project Management for Manufacturing

Improving a manufacturing control system

How to improve a manufacturing control system? Look no further! In today's fast-paced manufacturing environment, it's crucial to have an efficient and streamlined process. By implementing a digital version of your manufacturing process control plan, you can easily make changes on the fly, without wasting paper or losing data.

Start by creating control specifications and assigning tasks to team members. This ensures that everyone knows their role in the manufacturing process, from ordering raw materials to scheduling production runs. With business enterprise resource planning (ERP) software solutions like Level KATANA, you can streamline these processes and stay on top of everything in real-time.

When you're ready to take your manufacturing business to the next level, consider trying out Level KATANA for yourself with their 14-day free trial. You'll be able to see firsthand how this software can help you better manage your moving parts and turn raw materials into finished products efficiently. Don't let wasted paper or lost data hold back your manufacturing process any longer - upgrade now with Level KATANA!

Here's an interesting read: Manufacturing Quality Control

Discover the Vital Functions of Quality Control Roles

Quality control plays pivotal roles in ensuring that larger manufacturing production systems run smoothly. Specific roles are crucial, ranging from raw materials testing to final product checks before shipping. Quality control lets manufacturers ensure that their products meet customer expectations and comply with regulatory standards. From product reliability to safety, quality control is essential to any manufacturing process.

For another approach, see: Remote Control Construction Machines

1. Automate Workflow to Streamline Production

Workflow automation is crucial in keeping teams focused on important work and ensuring greater quality in manufacturing control. By assigning tags to specific team members, the production line can be streamlined with set task approvals that move quality forward. This process ensures quality control is consistently met while reducing potential errors from manual intervention.

Automation allows for a more efficient workflow, allowing workers to focus on important tasks rather than worrying about mundane ones. This can lead to increased productivity and overall better results. With the proper implementation of workflow automation, manufacturing control can be optimized for maximum efficiency and quality assurance.

2. Manage Risk and Track Issues

One of the most important aspects of manufacturing control is risk management. With a risk management feature in place, you can assess potential risks and assign a likelihood to them. This helps you manage risks and avoid unexpected impacts on your project. Additionally, you can scope cost and delivery display risk cards showing priority assignee, add attachments, and receive real-time updates.

A collaborative platform connects quality control managers and helps identify and resolve quality issues. This tool helps manufacturing manage their risks by providing access to customizable reports and allowing them to share updates with team members. By using this platform, manufacturers can stay up-to-date on potential risks and ensure that they are taking the necessary steps to mitigate those risks. Ultimately, this allows for better overall management of manufacturing projects and ensures that they are completed successfully.

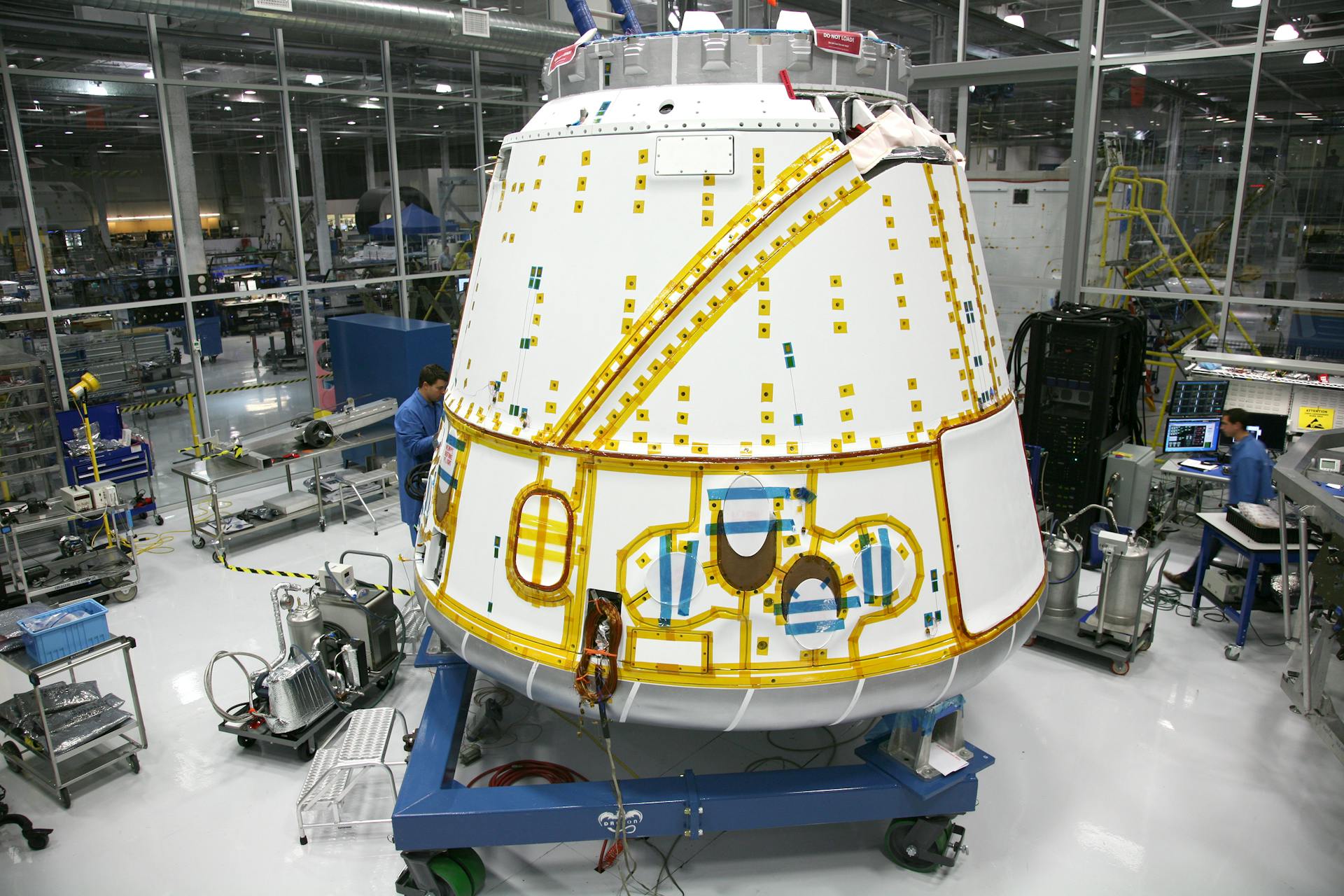

How the Manufacturing Process Works: From Start to Finish

The manufacturing process is a complex and intricate procedure that involves various stages from start to finish. These stages involve controlled variables such as raw materials, equipment, and labor to transform the initial product design into a finished product. Each stage of the process involves specific tasks and operations that are carefully planned and executed to ensure the quality of the final product.

However, not all variables can be controlled during the manufacturing process. Uncontrolled variables such as environmental factors or human error can cause disruptions in the production line, leading to delays or defects in the final product. To minimize these risks, manufacturers implement effective manufacturing control systems that monitor and manage each stage of production.

Overall, a successful manufacturing process requires careful planning, precise execution of tasks, and effective management of both controlled and uncontrolled variables. By implementing appropriate manufacturing control measures, companies can streamline their production lines, reduce costs, enhance quality control, and ultimately deliver better products to their customers.

Intriguing read: Discrete vs Process Manufacturing

How a Manufacturing Control Plan Improves Production Quality

A manufacturing control plan is a set of specific guidelines that helps process control management create and maintain consistency in the production process. By implementing this plan, manufacturers can ensure that every step of the manufacturing process meets the required standards for quality and efficiency. By doing so, they are able to reduce waste, minimize errors and defects, and ultimately improve overall production quality.

Quality Control vs. Quality Assurance

When it comes to manufacturing control, you'll hear "quality control" and "quality assurance" interchanged often. But what do they really mean? Quality control refers to the things done to ensure that the product you're manufacturing meets quality requirements. This includes test procedures and other checks throughout the production process.

On the other hand, quality assurance is a larger quality management process that ensures that the product you're manufacturing meets all quality requirements from start to finish. This includes a quality management plan and procedures in place for meeting those requirements. Essentially, quality assurance is about preventing defects before they happen while quality control takes place after production has started.

While both are important, quality control focuses on catching any issues with the product as it's being made while quality assurance prevents those issues from occurring in the first place. Ultimately, ensuring that your product meets all necessary quality requirements is crucial to its success in the market. By verifying through both quality control and quality assurance measures, you can catch any potential issues with the product that'll impact its overall performance and customer satisfaction.

Discover the Significance of a Manufacturing Control Plan

A manufacturing control plan is a concise roadmap that outlines specific steps to ensure the manufacturing process runs smoothly. It includes controlled variables, which are elements of the manufacturing process that can be manipulated or monitored, and uncontrolled variables, which cannot. A good control plan ensures that all required outputs meet quality requirements outlining by the company.

A well-designed control plan helps manufacturers avoid potential problems by identifying and addressing them before they become major issues. This allows them to react quickly to changes in the process, ensuring that quality is maintained throughout production. By creating a comprehensive control plan, manufacturers can ensure that their products meet the required quality standards and are delivered on time to customers.

In conclusion, a manufacturing control plan plays a crucial role in ensuring that the manufacturing process meets the company's quality requirements. It helps manufacturers identify and address potential problems before they occur and provides a roadmap for how to react quickly to changes in the process. By having a good control plan in place, manufacturers can ensure that their products are of high quality and delivered on time to customers.

If this caught your attention, see: Manufacturing Lead Time

Frequently Asked Questions

What is FDA Food and Drug Administration?

The FDA or Food and Drug Administration is a federal agency responsible for ensuring the safety and effectiveness of food, drugs, and medical devices sold in the United States. They regulate everything from prescription drugs to cosmetics, aiming to protect public health by enforcing strict guidelines and conducting research.

What are some quality control methods used in manufacturing?

Some quality control methods used in manufacturing include statistical process control, Six Sigma methodology, and Total Quality Management (TQM).

What is Federal Food and Drug Administration?

The Federal Food and Drug Administration (FDA) is a government agency responsible for regulating food, drugs, cosmetics, medical devices, and other products to ensure they are safe and effective for public use.

What are the benefits of quality control in manufacturing?

Quality control in manufacturing ensures that products meet specific standards and requirements, which results in consistent quality, increased customer satisfaction, reduced waste, and lower costs.

What is the production planning method?

Production planning method is a systematic approach used in manufacturing to decide how to produce goods efficiently, with the right quantity and quality, at the right time, and within budget. It involves analyzing demand, capacity, inventory levels, and resources to create a production schedule that maximizes productivity while minimizing waste.

Featured Images: pexels.com