A free piston linear alternator is a type of engine that uses a linear motion to generate electricity. It's a fascinating technology that's gaining attention for its potential to improve efficiency and reduce emissions.

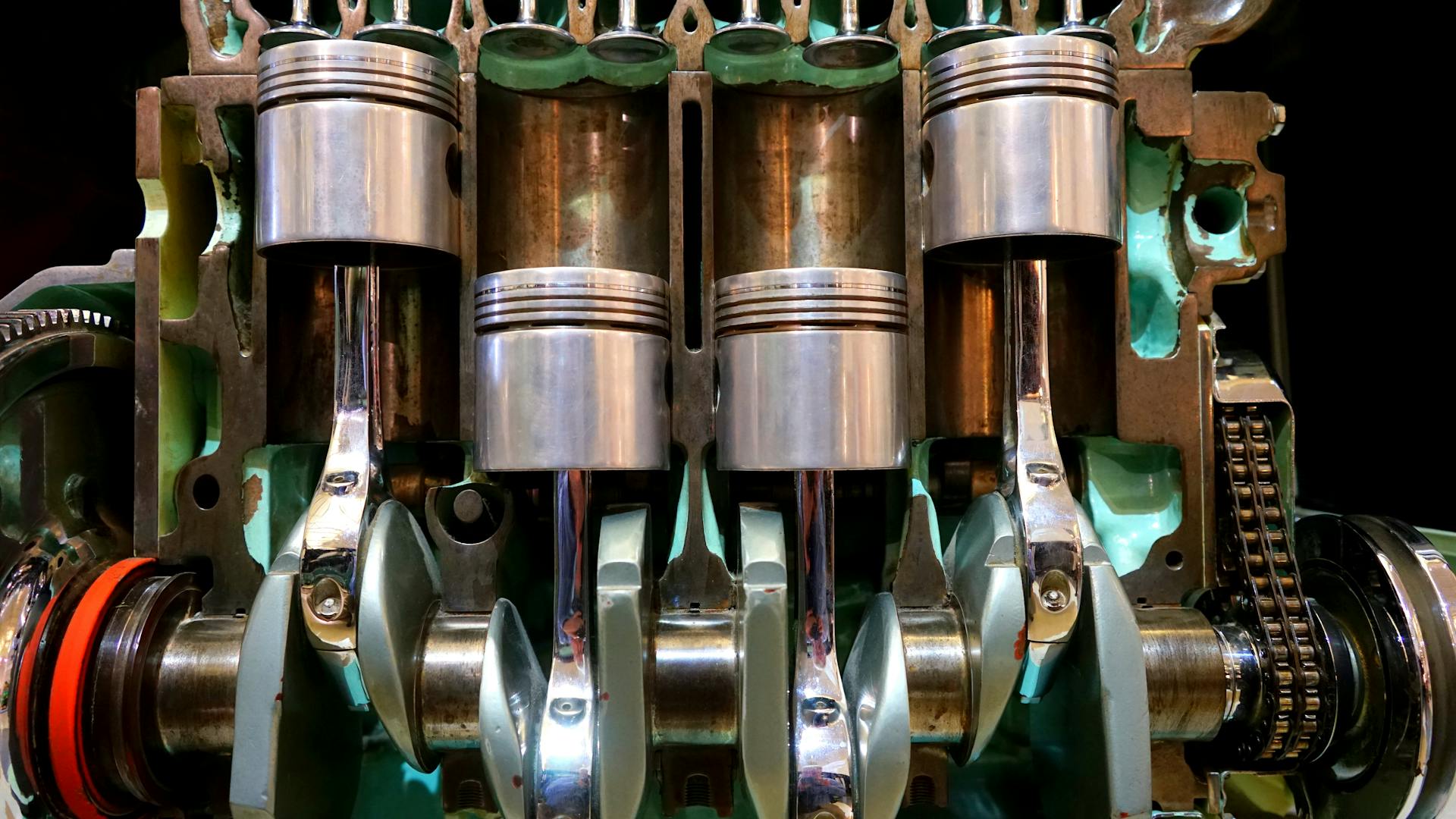

The free piston linear alternator works by using a piston that moves back and forth in a linear motion, driven by a combination of springs and combustion. This motion is then converted into electrical energy through an alternator.

The alternator is the heart of the system, and it's responsible for converting the linear motion into electrical energy. It's a crucial component that requires careful design and modeling to ensure efficient operation.

The free piston linear alternator has several advantages over traditional engines, including higher efficiency and lower emissions.

Additional reading: Another Name for an Ac Generator Is the Alternator

Description and Development

The free-piston linear alternator can be divided into three main subsystems: the reaction section, the linear electric generator, and the return unit. The reaction section typically consists of one or more reaction sections with a single or two opposite pistons.

See what others are reading: Free Piston Engine Linear Generator

The linear electric generator is a key component, composed of a static part (the stator) and a moving part (the magnets) connected to the connection rod. This design allows for a smaller and lighter generator with fewer parts compared to traditional electric generators.

The absence of a crankshaft is a significant advantage, enabling a variable compression and expansion ratios, which makes it possible to operate with different kinds of fuel. This flexibility is a major benefit of the free-piston linear alternator.

The technology has a long history, with the first patents dating back to around 1940. However, it wasn't until the development of rare-earth magnets and power electronics that researchers began to actively work on the technology.

Some notable research groups working on the free-piston linear alternator include:

- Libertine LPE, UK

- West Virginia University (WVU), USA

- Chalmers University of Technology, Sweden

- German Aerospace Center (DLR), Germany

Description

The free-piston engine linear generator is a complex system that can be broken down into three main subsystems. The first subsystem is the reaction section, which can have one or more pistons, either single or in pairs.

The linear electric generator is the second subsystem, consisting of a static part called the stator and a moving part called the magnets connected to the connection rod. This setup allows for the control of the resistance force and, consequently, the piston's movement and reaction.

A return unit is necessary to push the piston back due to the absence of a crankshaft, which is typically a gas spring or an opposed reaction section. This is a crucial component that enables the free-piston engine linear generator to operate efficiently.

The FPLG has several advantages over traditional electric generators powered by internal combustion engines. One of the main benefits is the absence of a crankshaft, which results in a smaller and lighter generator with fewer parts.

A variable compression and expansion ratio is also possible with the FPLG, making it suitable for operation with different kinds of fuel. This flexibility is a significant advantage in various applications.

The total efficiency of free-piston linear generators can be significantly higher than conventional internal combustion engines and comparable to fuel cells.

Broaden your view: Electrostatic Generators

Development

The development of free-piston linear generators has been a long and winding road, with the first patents dating back to around 1940.

One of the earliest pioneers in this field was Electric Generator, Pontus Ostenberg, who patented his design in 1943 in the USA.

The technology gained momentum in the last few decades, thanks in part to the development of rare-earth magnets and power electronics.

Research groups from around the world have been working on this technology, including Libertine LPE from the UK, West Virginia University from the USA, and Chalmers University of Technology from Sweden.

Here's a list of some of the notable research groups working on free-piston linear generators:

- Libertine LPE, UK

- West Virginia University (WVU), USA

- Chalmers University of Technology, Sweden

- Aquarius Engines, Israel

- Free Piston Engine Project, Newcastle University, UK

- Shanghai Jiaotong University, China

- Free-Piston Linear Generator, German Aerospace Center (DLR), Germany

- Free Piston Power Pack (FP3), Pempek Systems, Australia

- Free Piston Energy Converter, KTH Electrical Engineering, Sweden

- Linear Combustion Engine, Czech technical university

- Internal Combustion Linear Generator Integrated Power System, Xu Nanjing, China

- micromer ag, Switzerland

- Free-piston engine linear generator, Toyota, Japan

The variety of names and abbreviations for this technology can be overwhelming, but the terms "Free-piston linear generator" and "FPLG" are commonly used to refer to the project at the German Aerospace Center.

The DLR Research

The DLR research is a significant development in the field of free piston linear alternators. The German Aerospace Center's Institute of Vehicle Concepts has been working on this project since 2002.

They've made tremendous progress, and in 2013, they successfully built and operated the first entire system. This achievement marked a major milestone in the project.

The team is currently working on the second version of the entire system, which uses two opposed cylinders to reduce vibration and noise. This improvement makes the technology more viable for the automotive industry.

The use of opposed cylinders is a notable innovation in this project. It's a clever solution to a common problem in engine design.

Here's a brief overview of the key players involved in the FPLG project:

- DLR (German Aerospace Center)

- Institute of Vehicle Concepts

Modeling

Modeling is a crucial aspect of free piston linear alternator (FPLA) design. The model consists of a dynamic calculation of the piston motion and a thermodynamic calculation of the engine's thermodynamic events.

The piston motion is governed by the interaction of forces that act on the piston simultaneously, which are in-cylinder pressure force from each cylinder, electromagnetic force, friction force, and inertia force. This is shown in Fig.2.

The FPLA operates on the same basic physical principles as conventional rotary alternators. The principle that governs the voltage generating operation of the alternator is Faraday's law.

The dimension of a physical quantity is associated with combinations of mass, length, time, temperature, and heat quantity. The basic variables that involved were defined based on the dynamic and thermodynamic modeling of FPLA, and are listed in the table below:

Variations

The free-piston linear generator's versatility is impressive, and one reason for this is the various configurations it can be designed in.

In most automotive applications, the focus has been on two opposed pistons in the same cylinder with one combustion chamber and a gas spring at the end of each cylinder.

A simpler configuration uses a second unit that's just a mirror of the first, with no functional connection to the first.

Alternatively, a single combustion chamber or gas spring can be used, allowing for a more compact design and easier synchronization between the pistons.

The gas spring and combustion chamber can be placed on the ends of the connection rods, or they can share the same piston, using opposite sides to reduce space.

The linear generator itself can be designed as a round tube, a cylinder, or even a flat plate to reduce the center of gravity and/or improve heat dissipation.

Here are some possible configurations for the linear generator:

- Round tube

- Cylinder

- Flat plate

The absence of a crankshaft gives the engine a degree of freedom, removing a great pumping loss and allowing for two-stroke or four-stroke engines.

However, a four-stroke engine requires a much higher intermediate storage of energy, the rotational inertia of the crankshaft, to propel the piston through the four strokes.

Most current research focuses on the two-stroke cycle because it doesn't require this higher energy storage.

The combustion process can be designed in different ways, including:

- Spark ignition (Otto)

- Compression ignition (Diesel)

- Homogeneous charge compression ignition (HCCI)

Dynamic Modeling

Dynamic modeling is a crucial step in understanding the behavior of a Free Piston Linear Alternator (FPLA). It involves a dynamic calculation of the piston motion and a thermodynamic calculation of the engine's thermodynamic events.

The piston motion is governed by the interaction of forces acting on the piston simultaneously, including in-cylinder pressure force, electromagnetic force, friction force, and inertia force.

To accurately model the piston motion, researchers have already developed dynamic models of FPLA and numerical simulations of its performance. These models typically consist of a dynamic calculation of the piston motion and a thermodynamic calculation of the engine's thermodynamic events.

The modeling process requires careful consideration of various parameters, including the effective stroke length to bore ratio and the ignition compression ratio. These parameters can significantly impact the piston motion and the overall performance of the FPLA.

Here's a summary of the different CFD calculation cases studied:

Dimensionless Modeling of FPLA

Dimensionless modeling of FPLA is a crucial step in understanding the behavior of this complex system. It involves identifying the fundamental variables and their dimensions, which are listed in Table 1.

The variables include bore, piston area, volume of the cylinder, effective stroke length, total stroke length, translator ignition position, mass of the translator, load coefficient, friction force, energy, scavenge pressure, scavenge temperature, pressure, gas constant, temperature, wall temperature, combustion duration, compression ratio, indicated efficiency, effective efficiency, time, and frequency.

These variables have different dimensions, including length ([L]), mass ([M]), time ([T]), temperature ([θ]), and heat quantity ([H]). Heat quantity is also a kind of energy, so its dimension is replaced with [MLT].

The dimensionless load coefficient has a significant impact on the operating conditions of FPLA. Increasing the load coefficient can lead to higher electromagnetic forces, which in turn affect the compression ratio and frequency of the translator.

Here's a summary of the variables and their dimensions:

Frequently Asked Questions

What is the difference between a linear generator and a rotary generator?

A direct drive linear electrical generator eliminates the need for mechanical interfaces, unlike conventional rotary generators which require gearboxes, pumps, and turbines. This design simplifies the system and reduces mechanical losses, making it more efficient and compact.

What is the efficiency of a linear alternator?

A linear alternator operates at 99% efficiency. This high efficiency is a significant improvement over its predecessors.

Featured Images: pexels.com