A DC generator and an alternator are two types of electrical generators that convert mechanical energy into electrical energy.

A DC generator produces direct current, which is a type of electrical current that flows in one direction only.

The key difference between a DC generator and an alternator lies in the type of current they produce.

A DC generator uses a commutator to convert the alternating current generated by the rotor to direct current.

In contrast, an alternator uses a rotor and stator to generate alternating current.

The output of a DC generator is a direct current, which is typically used in applications such as battery charging and power supplies.

An alternator, on the other hand, produces alternating current, which is commonly used in applications such as automotive electrical systems and power grids.

DC Generator Basics

A DC generator is a machine that converts mechanical energy into DC electricity.

The principle of electromagnetic induction is the key to how a DC generator works.

The DC generator uses a conductor that slashes magnetic flux to generate an electromotive force (emf).

This emf causes a flow of current when the conductor circuit is closed.

The direction of the induced current changes whenever the direction of motion of the conductor changes, according to Fleming's right-hand rule.

A split ring commutator is used to reverse the connections of the armature conductors when the current reverses, resulting in unidirectional current at the terminals.

The DC generator is based on Faraday's law of electromagnetic induction, where an emf is induced in a conductor when it cuts through a magnetic field.

The magnetic field and conductor are the two essential parts of a generator, and the rotating coil is called an armature.

The armature is made of copper and is connected by two slip rings to collect the induced current and transfer it to the external load resistance.

If this caught your attention, see: Direct Current Electric Generator

What is a Generator?

A generator is a device that converts mechanical energy into electrical energy by using an external source of mechanical energy to rotate a coil of wire within a magnetic field.

This movement of the wire/coil within the magnetic field induces an electrical current in the wire, which can then be harnessed as electrical power.

Generators can be powered by a range of sources, including gasoline, diesel, natural gas, or renewable energy sources like wind or hydroelectric power.

They can vary in size and capacity, ranging from small portable units that can power a few small devices, to large industrial generators capable of producing hundreds or thousands of kilowatts of power.

Generators work based on the principle of Faraday’s laws of electromagnetic induction, where EMF is induced whenever the conductors cut the magnetic flux.

For more insights, see: How Electrical Generators Work

What Is a Generator?

A generator is a device that converts mechanical energy into electrical energy.

Generators use an external source of mechanical energy, such as a turbine, engine, or crankshaft, to rotate a coil of wire within a magnetic field.

This movement of the wire/coil within the magnetic field induces an electrical current in the wire.

Generators are powered by a range of sources, including gasoline, diesel, natural gas, or renewable energy sources like wind or hydroelectric power.

They can produce AC or DC power, with some generators including features like automatic voltage regulation or backup power systems.

Generators vary in size and capacity, from small portable units to large industrial generators that can produce hundreds or thousands of kilowatts of power.

A generator's working is based on the principle of Faraday’s laws of electromagnetic induction.

The magnetic field and conductor are two essential parts of the generator.

Generators consist of a rectangular rotating coil that rotates in a magnetic field around its axis.

The ends of the coil are connected by two slip rings that collect the induced current in the coil and transfer it to the external load resistance R.

The rotating coil is called an armature, which is made of copper.

For your interest: Does a Generator Produce Ac or Dc

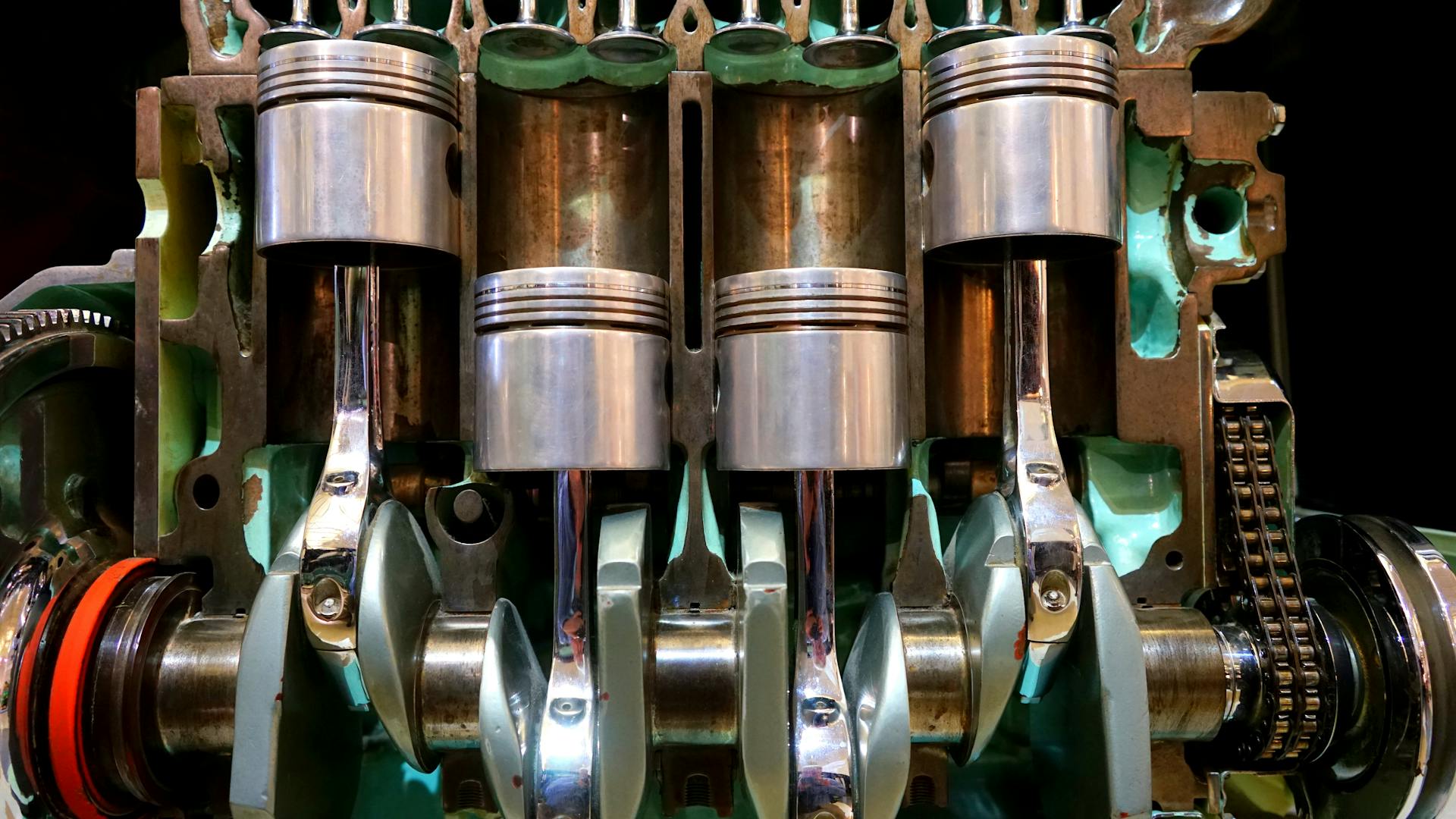

How Generators Work

Generators work on the principle of electromagnetic induction. This means that they use a conductor coil to generate an electric current when it's rotated rapidly between the poles of a magnet.

A conductor coil, also known as an armature, is made of a copper coil tightly wound onto a metal core. This coil is the heart of the generator, and its movement within a magnetic field is what creates the electrical current.

The magnetic field is provided by either permanent magnets or electromagnets. The armature is connected to two slip rings, which collect the induced current and transfer it to an external load resistance.

As the armature rotates, it cuts through the magnetic field, inducing an electromotive force (EMF) in the conductor. This EMF causes the current to flow when the conductor is closed.

Generators can use a range of sources to power the armature, including gasoline, diesel, natural gas, or renewable energy sources like wind or hydroelectric power.

The movement of the armature within the magnetic field is what creates the alternating current (AC) or direct current (DC) that we use to power our devices.

Alternator vs DC Generator

An alternator always induces an alternating current, whereas a DC generator produces direct current. The electrical current induced by an alternator reverses direction periodically, whereas a DC generator's current flows only in one direction.

In terms of design, an alternator's magnetic field always rotates inside the stator, whereas a DC generator has a fixed magnetic field. This difference in design affects the output of each device, with an alternator producing AC and a DC generator producing DC.

Here's a comparison of the two:

Generator vs Alternator

A generator is a mechanical device that converts mechanical energy to either AC or DC electrical energy. This makes it a versatile tool for various applications.

A generator can generate either alternating or direct current, depending on its design. This is in contrast to an alternator, which always induces an alternating current.

An alternator is a device that converts mechanical energy into AC electrical energy. It's specifically designed for generating AC power, making it a crucial component in many electrical systems.

One of the key differences between a generator and an alternator is their output. A generator can produce both AC and DC power, while an alternator only produces AC power.

Here's a comparison of the two:

In summary, a generator is a more general term that encompasses both AC and DC generators, while an alternator is a specific type of device that generates AC power.

Alternator Function

An alternator is a device that converts mechanical energy into electrical energy, using a rotor and stator to create a rotating magnetic field.

This magnetic field induces a voltage in the stator's conductive coils, generating an alternating current (AC) output.

The AC output is then converted to direct current (DC) using a rectifier, which is necessary for most applications that require DC power.

A voltage regulator is also typically used to control the output voltage, ensuring it remains within a certain range to prevent damage to the electrical system.

The alternator's rotor is powered by a drive belt that turns the alternator's rotor shaft, spinning a set of magnets around a coil.

This process is similar to how a generator works, but with some key differences that set them apart.

An alternator is designed to produce AC power, whereas a generator is designed to produce DC power.

The alternator's ability to produce AC power makes it a crucial component in many applications, including automobiles, power plants, and industrial equipment.

Additional reading: Gen Set Generator

Alternator Function

An alternator converts mechanical energy into electrical energy, using a rotor and stator to generate an alternating current (AC) output. This AC output is typically converted to direct current (DC) using a rectifier, which is necessary for most applications.

The rotor is a rotating magnet that creates a rotating magnetic field as it spins. The stator, a stationary set of conductive coils, induces a voltage in the coils as the magnetic field passes by.

A voltage regulator controls the output voltage to ensure it remains within a certain range, preventing damage to the electrical system and ensuring efficient operation.

Alternator Feedback Loop

Alternators have a built-in feedback loop that regulates the output voltage to ensure the battery gets fully charged. This loop is controlled by a voltage regulator (VR) that senses the system voltage and adjusts the excitation current to maintain a charging-system voltage between 13.8 and 14.2 volts in a 12-volt system.

The VR works by varying the excitation current flow to keep the system voltage within a safe range. If the system voltage goes above 16 volts (for 12-volt systems) or 32 volts (for 24-volt systems), the overvoltage relay (OVR) cuts off the excitation current and the alternator output drops to zero.

A malfunctioning VR can cause the voltage output to skyrocket, leading to costly overvoltage system meltdowns. This is why pilots should be aware of the symptoms of a malfunctioning VR, such as acrid clouds of smoke and equipment failure.

Fortunately, most modern alternators have built-in overvoltage protection, which prevents these meltdowns. This protection is designed to automatically open the circuit between the bus and the alternator control unit (ACU) whenever the system voltage exceeds a safe threshold.

If the system won't reset after attempting to turn off and on the alternator switch, pilots should shed electrical load and evaluate their options. This may involve replacing the malfunctioning VR or seeking professional help to diagnose and repair the issue.

Recommended read: How to Run Ac off Generator

Transmission Distribution

Transmission distribution is a crucial aspect of an alternator's function. The AC generators can efficiently distribute the AC current easily through the transformer.

AC current has an advantage when it comes to distribution. This is because transformers can be used to step up or step down the voltage, making it easier to transmit over long distances.

Transformers are essential for efficient distribution of AC current. They allow for the transformation of voltage levels, making it possible to transmit power over long distances with minimal loss.

The DC generators, on the other hand, have a hard time distributing the current. This is because transformers cannot be used in this case, making it difficult to transmit the power over long distances.

As a result, AC generators are often preferred for applications that require efficient transmission of power.

Discover more: How Long Do Portable Generators Last

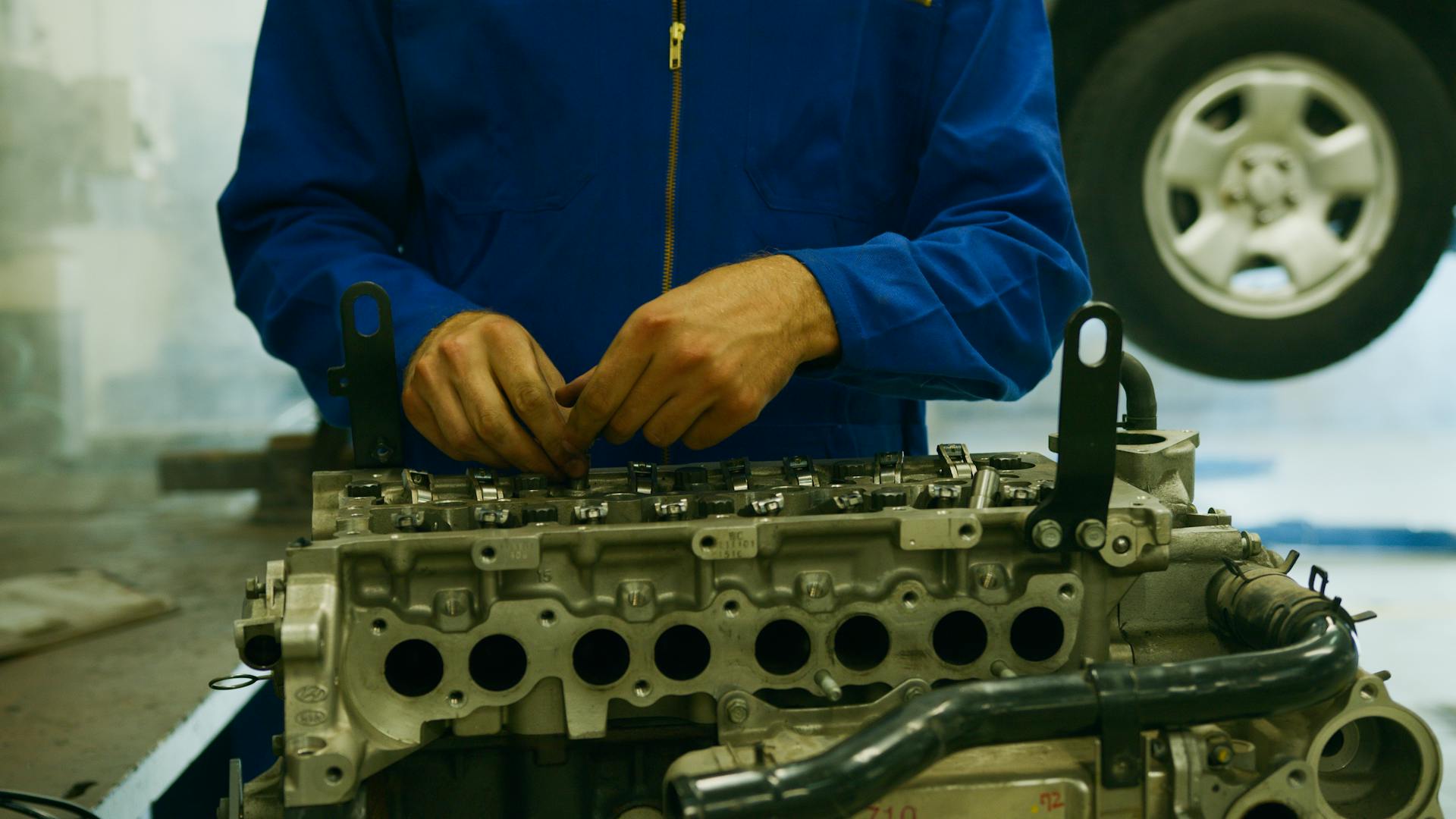

Troubleshooting and Maintenance

Troubleshooting and maintenance are crucial for keeping your aircraft's electrical system running smoothly. One of the best tools for troubleshooting rectifier problems is an alternator ripple tester.

Many pilots have modified the owner's manual starting procedure by leaving the alternator half of the switch in the Off position until after the start sequence. This helps prevent large voltage spikes from affecting charging-system components during engine starting.

Generators typically require more maintenance than alternators, mainly because they have brushes and commutators that wear out over time.

Troubleshooting

Troubleshooting is a crucial part of aircraft maintenance, and having the right tools can make all the difference. An alternator ripple tester is a valuable tool for identifying rectifier problems.

Many pilots have modified the owner's manual starting procedure by leaving the alternator half of the switch in the Off position until after the start sequence. This helps prevent large voltage spikes from damaging charging-system components.

The potential for large voltage spikes rippling through the electrical system is very high during engine starting. This is because contactors that control large current flows are opening and closing rapidly.

To verify that the charging system is online, pilots can turn on the alternator half of the switch after starting the engine and check for positive movement of the ammeter needle.

Maintenance

Maintenance is a crucial aspect of keeping your electrical systems running smoothly.

Generators typically require more maintenance than alternators, which can be a significant consideration for those who rely on them.

This is because generators have brushes and commutators that wear out over time, needing to be replaced when necessary.

Regular maintenance can help prevent costly repairs and ensure your electrical system is functioning properly.

Efficiency and Performance

AC generators are pretty efficient and have a lower energy cost. DC generators, on the other hand, are less efficient due to sparks and losses in terms of eddy current, copper, hysteresis, and mechanical.

These losses in DC generators result in wasted energy, which can add up over time. AC generators, with their lower energy cost, can help you save money on your electricity bills.

DC generators constantly have sparks, which can be a major drawback. In contrast, AC generators are designed to minimize energy loss and maximize efficiency.

Overall, AC generators seem to have the upper hand when it comes to efficiency and performance.

Related reading: Seebeck Generator Efficiency

Safety and Risks

AC generators have a less likely risk of short circuits due to their highly efficient brushes.

The risk of short-circuiting is higher in DC generators, whose commutators and brushes wear out quickly.

DC generators are more prone to overheating, which can lead to a higher risk of electrical shock.

In contrast, AC generators are generally safer in this regard.

Cost and Design

The design of a generator can greatly impact its overall cost and efficiency. The AC generator has a simpler design, with the coil fixed to the generator and the magnet movable, making it less costly to construct.

However, the DC generator has a more complex design, with the coil rotating in a fixed field, which can make construction more challenging, especially when it comes to slip rings and commutators.

The cost of a generator is also an important consideration. AC generators are initially more expensive, but their lower maintenance costs make them more cost-effective in the long run.

Readers also liked: Ac Generator Cost

Cost

When considering the cost of generators, it's essential to look beyond the initial purchase price. The cost of AC generators is initially high, but due to the less maintenance cost, it doesn’t add up as much.

This means that AC generators can be a more cost-effective option in the long run. The maintenance cost of AC generators is significantly lower compared to DC generators.

On the other hand, DC generators are less costly upfront, but their high maintenance cost actually makes them more expensive with time.

Design

The design of a generator can greatly impact its overall cost and efficiency. The AC generator has a simpler design, with the coil fixed in place and the magnet movable.

In contrast, the DC generator has a coil that rotates in a fixed field, making its construction more complex. This is especially true for the slip rings and commutators, which require more precise engineering.

The AC generator's design is indeed less costly, likely due to the fewer moving parts involved.

Frequently Asked Questions

Why has the alternator replaced the DC generator in most types of vehicles?

The alternator replaced the DC generator in most vehicles because it provides a higher current output, meeting the demands of modern vehicle systems. This upgrade ensures reliable power supply, even at low idle speeds.

Sources

- https://www.toppr.com/guides/physics/difference-between-ac-and-dc-generator/

- https://www.aopa.org/training-and-safety/students/solo/special/alternators-and-generators

- https://www.electronicshub.org/difference-between-a-generator-and-an-alternator/

- https://acepowerparts.com/blog/ac-alternator/

- https://mechanicrealm.com/alternator-vs-generator/

Featured Images: pexels.com