Electrical generators are essential devices that convert mechanical energy into electrical energy. They work by using a magnetic field to induce an electric current in a conductor.

The basic principle behind an electrical generator is the electromagnetic induction discovered by Michael Faraday in 1831. This principle states that an electric current is generated when a conductor moves through a magnetic field.

A simple electrical generator consists of a rotor and a stator. The rotor is the moving part that spins inside the stator, which is the stationary part. The rotor has magnets attached to it, while the stator has coils of wire wrapped around it.

As the rotor spins, it creates a changing magnetic field that induces an electric current in the coils of the stator. This current is then collected and sent to a power grid or used directly by a device.

Suggestion: Direct Current Electric Generator

How Electrical Generators Work

Generators don't actually create electricity, they convert mechanical or chemical energy into electrical energy. This process involves capturing the power of motion and turning it into electrical energy by forcing electrons from an external source through an electrical circuit.

The modern generators work on the principle of electromagnetic induction discovered by Michael Faraday. He realized that moving an electrical conductor in a magnetic field creates a voltage difference between the two ends of the conductor, causing electric charges to flow and generate electric current.

Generators are essentially electrical motors working in reverse, capturing the power created by water turning turbines or traditional fuel sources like diesel, gas, and propane to create mechanical power that can then be forced into a circuit and induce an electrical current.

To create electricity, an electrical generator uses the mechanical energy supplied to it to force the movement of electric charges present in the wire of its windings through an external electric circuit. This flow of electrons constitutes the output electric current supplied by the generator.

The flow of electricity is directed through copper wires to power external machines, devices, or entire electrical systems. This process is similar to how a pump pushes water through a pipe.

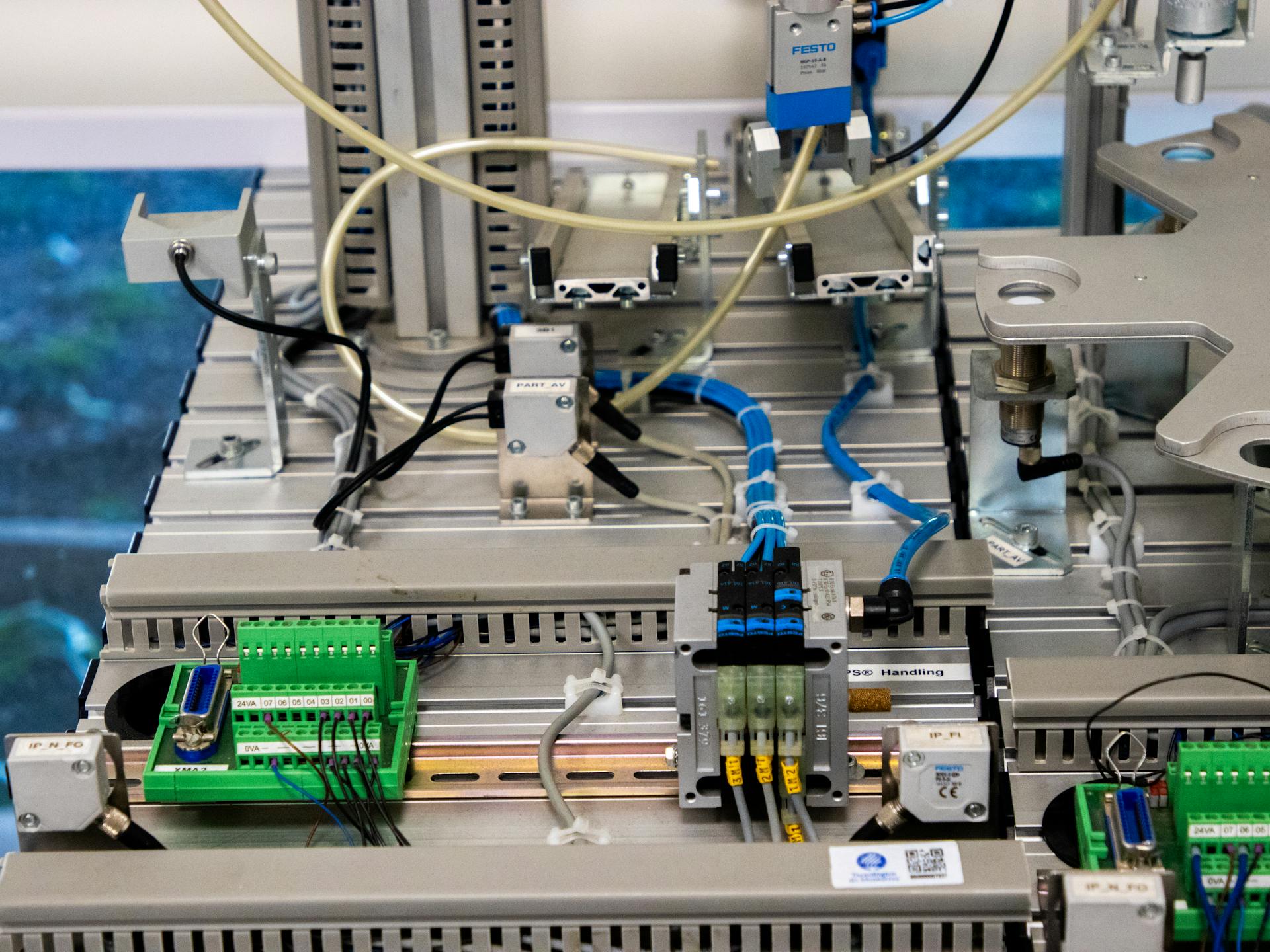

Here are the 9 main parts of a generator:

- Engine: The engine supplies energy to the generator and determines how much electricity it can provide.

- Alternator: This is where the conversion from mechanical energy to electrical energy occurs, creating the electromagnetic field and movement of electrons that generates electricity.

- Fuel System: The fuel system makes it possible for the generator to produce the energy needed, including a fuel tank, fuel pump, pipe, and return pipe.

- Voltage Regulator: This component helps control the voltage of the electricity produced and convert it from AC to DC if needed.

- Cooling and Exhaust Systems: Generators create a lot of heat, and the cooling system ensures the machine doesn't overheat, while the exhaust system directs and removes the fumes formed during operation.

- Battery Charger: Batteries are used to start up the generator, and the battery charger ensures the battery is ready to go when needed by supplying it with a constant low-level of voltage.

- Control Panel: The control panel controls every aspect of generator operation, from start-up and running speed to outputs.

- Main Assembly/Frame: This is the body of the generator, the part that holds it all in place.

The fumes emitted by generators are just like the exhaust given off by other gas or diesel-powered engines, including toxic chemicals like carbon dioxide, which must be filtered and removed from emissions.

Types of Generators

There are two main types of electric generators: AC and DC generators. AC generators are limited to 25 kW and are known as single-phase generators.

AC generators are used in various applications, but their power output is capped at 25 kW. DC generators, on the other hand, are divided into three categories: shunt, series, and compound-wound.

Shunt generators are commonly used in battery chargers, while series generators are used in street lights. Compound-wound generators are the most common type of DC generator.

If this caught your attention, see: How Is a Shunt Wound Dc Generator Connected

Specialized Types

Generators come in various specialized types to cater to specific needs.

Portable generators are designed for convenience, allowing users to move them around easily, making them perfect for camping trips or outdoor events.

They usually range from 2000 to 10,000 watts, with some smaller models even fitting in a car trunk.

Inverter generators are known for their quiet operation and ability to provide clean power for sensitive electronics.

They're commonly used for RVs and small homes, where a reliable and quiet power source is essential.

Diesel generators are often used for heavy-duty applications, such as powering large construction sites or industrial equipment.

They're typically more expensive to purchase and maintain than other types, but offer higher power output and longer engine life.

Standby generators are designed to automatically kick in during power outages, providing a reliable backup power source.

They're usually installed outside the home or business, and can be connected to a natural gas line for fuel.

Here's an interesting read: Can a Ac Motor Be Used as a Generator

Genset

A genset is a self-contained piece of equipment that combines an electrical generator and an engine, also known as a prime mover. The engine is usually a piston engine, but gas turbines and hybrid diesel-gas units are also used.

Many different versions of gensets are available, ranging from small portable petrol powered sets to large turbine installations. The primary advantage of gensets is their ability to independently supply electricity, making them useful as backup power sources.

Gensets are designed to be compact and portable, making them easy to transport and set up in emergency situations. They're often used in remote areas or during power outages.

The engines used in gensets emit fumes that contain toxic chemicals like carbon dioxide, which must be filtered and removed from emissions.

Variable-Speed

Variable-Speed generators can deliver power at a constant frequency, but they require a narrow range of prime mover speeds to function properly.

Grid-connected generators, for example, need a specific speed to deliver power at the required utility frequency. This can be a challenge, especially in situations where tightly regulating the speed of the prime mover is impractical or undesired.

Doubly fed electric machines can be used as generators to regulate the output frequency over a wider range of generator shaft speeds. This is made possible with the assistance of power electronic devices.

Using a standard generator with no frequency regulation and then converting the power to the desired output frequency with a rectifier and converter combination is another option. This approach can improve energy production, but it requires more complex generators and controls.

For instance, a wind turbine operating at fixed frequency might be required to spill energy at high wind speeds.

Linear Electric

A linear electric generator is a type of generator that uses a sliding magnet to induce an alternating current in a wire or coil.

This type of generator is often used in small applications, such as the Faraday flashlight, and can be scaled up for use in wave power schemes.

A sliding magnet moves back and forth through a solenoid, a copper wire or a coil, inducing an alternating current each time it slides through.

Generators like this work on the principle of electromagnetic induction, discovered by Michael Faraday, which states that a flow of electrons can be created by moving an electrical conductor in a magnetic field.

The movement of the magnet creates a voltage difference between the two ends of the conductor, causing the electric charges to flow and generating electric current.

In a linear electric generator, the movement of the magnet is what creates the flow of electrons, allowing the generator to produce electricity.

This type of generator is a great example of how mechanical energy can be converted into electrical energy, and is an important part of many modern power generation systems.

A fresh viewpoint: Free Piston Engine Linear Generator

Components and Structure

An electrical generator is made up of several key components, each playing a crucial role in producing electricity. The engine supplies the energy needed to generate power, and the alternator is where the magic happens, converting mechanical energy into electrical energy.

The alternator is a critical component, and it's where you'll find both moving and stationary parts working together to create the electromagnetic field and movement of electrons that generates electricity. This is often referred to as the "genhead".

The main assembly or frame of the generator is essentially its body, holding all the components together. It's the part you see, and it's what keeps everything in place.

Here are some of the key components of an electrical generator:

- Engine

- Alternator (genhead)

- Fuel System

- Voltage Regulator

- Cooling and Exhaust Systems

- Battery Charger

- Control Panel

- Main Assembly / Frame

Terminology and Definitions

Let's start with the basics. A generator is essentially made up of two broad categories: dynamos and alternators. Dynamos generate pulsing direct current through the use of a commutator.

The two main parts of an electrical machine are the rotor and the stator. The rotor is the rotating part, while the stator is the stationary part that surrounds it. One of these parts generates a magnetic field, while the other has a wire winding where the changing field induces an electric current.

In an electrical machine, the field winding or field magnets produce the magnetic field. This can be done using wire windings called field coils or permanent magnets. If a generator uses permanent magnets, it's sometimes called a magneto or a permanent magnet synchronous generator (PMSG).

The power-producing component of an electrical machine is called the armature. In a generator, alternator, or dynamo, the armature windings generate the electric current that provides power to an external circuit. The armature can be on either the rotor or the stator, depending on the design, with the field coil or magnet on the other part.

Here's a quick rundown of the key terms:

- Dynamo: generates pulsing direct current

- Alternator: generates alternating current

- Rotor: the rotating part of an electrical machine

- Stator: the stationary part of an electrical machine

- Field winding or field magnets: produce the magnetic field

- Armature: the power-producing component of an electrical machine

Rotor

The rotor is a crucial component of a synchronous generator, and it's what makes the whole machine work. It's essentially a cylindrical iron rotor with conductors or coils wound into slots cut into its surface.

These coils, known as the field winding, are connected in series and produce the magnetic field that interacts with the stator. The position of the field coils is carefully designed to create a sinusoidally distributed magnetic field in the air gap between the rotor and stator.

The magnetic field produced by the rotor is what induces an electric current in the stator, and it's a fundamental principle of how generators work. The relative motion between the magnetic field and the conductor creates an electric current, which is then harnessed to generate electricity.

In a power station, the rotor is often coupled to a mechanical prime mover, which provides the energy needed to turn the generator. This energy source can vary widely, but most power stations burn fossil fuels such as coal, oil, and natural gas to generate electricity.

Stator

The stator is a crucial component of a generator, and it's essentially a cylindrical ring made of iron that allows for easy passage of magnetic flux. This ring-like structure is designed to facilitate the flow of magnetic fields.

In the case of an elementary generator, the stator contains only one coil, which is divided into two sides that fit snugly into slots within the iron ring. The ends of the coil are connected together by curved conductors that wrap around the stator's periphery.

The coil itself typically consists of multiple turns, and it's where the magic happens in terms of voltage induction. As the rotor rotates, a voltage is induced in the stator coil, and its magnitude is directly proportional to the rate at which the magnetic field is changing with time.

The voltage will be maximum in one direction when the rotor has turned 90° from its initial position, and it will be maximum in the opposite direction 180° later. This results in a sine-waveform voltage pattern, as shown in Figure 1.

Frequently Asked Questions

Does an electric generator really generate an electric current?

An electric generator converts mechanical energy into electrical energy, but it doesn't create electricity from scratch. Instead, it converts existing energy into a usable electrical current.

Sources

- https://www.tevisenergy.com/how-does-a-generator-work/

- https://en.wikipedia.org/wiki/Electric_generator

- https://www.britannica.com/technology/electric-generator

- https://byjus.com/physics/the-electric-generator/

- https://www.criticalpower.com/company-profile/helpful-news-resources/how-electrical-generators-work/

Featured Images: pexels.com