A DC generator is a type of electrical machine that converts mechanical energy into direct current electricity. It's a fundamental component in many industrial and commercial applications, including power plants, hospitals, and even some homes.

The key to a DC generator's operation lies in its ability to produce a steady flow of electrical current. This is achieved through a process called electromagnetic induction, where a magnetic field is created within the generator's core.

The DC generator's core consists of a rotor and a stator, with the rotor being the moving part that spins within the stator. The rotation of the rotor creates a magnetic field that induces an electric current in the stator.

The DC generator's efficiency is directly related to its ability to maintain a consistent magnetic field. This is achieved through the use of a commutator, which reverses the direction of the current flow at regular intervals.

A unique perspective: How Do Electrical Generators Work

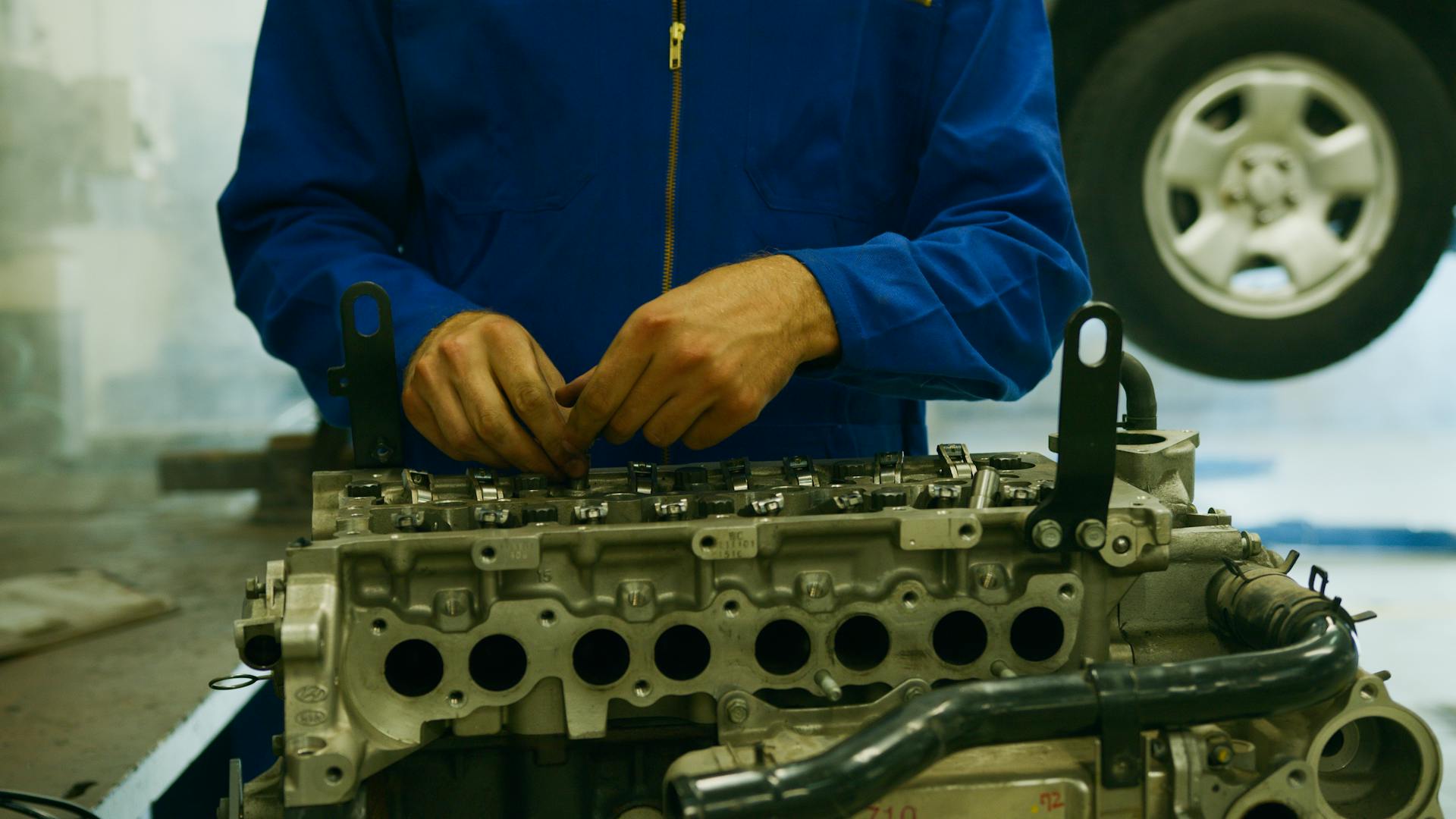

Parts and Construction

A DC generator is essentially a DC machine that can be used as a motor without any constructional changes. The main parts of a DC generator include the stator and rotor. The stator provides the magnetic field where the coil spins, and it includes two magnets with opposite polarities facing each other.

The rotor, also known as the armature core, is the heart of the DC generator. It's a cylindrical shape with slots to carry the armature winding. The armature core is built up of thin laminated circular steel disks to reduce eddy current losses.

The armature winding is usually a former-wound copper coil that rests in the armature slots. It's insulated from the armature core and other armature conductors. The armature winding can be wound in either lap or wave winding, with double layer lap or wave windings being the most common.

A DC generator also has a commutator and brushes. The commutator collects the current generated in the armature conductors, while the brushes provide a physical connection to the armature winding. The commutator consists of a set of copper segments insulated from each other, with the number of segments equal to the number of armature coils.

Here's a breakdown of the main parts of a DC generator:

- Yoke: The outer frame of the DC generator, made of cast iron or steel, providing mechanical strength and carrying magnetic flux.

- Poles and pole shoes: The poles carry the field winding, while the pole shoes support the field coils and spread out the flux in the air gap.

- Field winding: Usually made of copper, wound on each pole, and connected in series to form alternate North and South poles.

- Armature core (rotor): The cylindrical shape with slots to carry the armature winding, built up of thin laminated circular steel disks to reduce eddy current losses.

- Armature winding: Former-wound copper coil resting in the armature slots, insulated from the armature core and other armature conductors.

- Commutator and brushes: Collects current generated in the armature conductors and provides a physical connection to the armature winding.

Key Components

A DC generator is made up of several key components that work together to produce electricity. These components include the armature, commutator, and brushes.

The armature is the main component of a DC generator, where the magnetic field and electrical current interact. It's typically made of a copper wire coil that rotates within a magnetic field.

The commutator is a critical component that allows the DC generator to produce a direct current. It's a sliding contact that reverses the direction of the current as the armature rotates.

The brushes are small metal pieces that make contact with the commutator, transferring the electrical current to the external circuit.

You might enjoy: Dc Generator Components

Rotor

The rotor is a crucial component in a DC machine. It's made up of slotted iron laminations stacked to form a cylindrical armature core.

The function of the lamination is to decrease the loss caused due to eddy current. This is achieved by reducing the thickness of the iron, which in turn minimizes the eddy current loss.

Here's an interesting read: Direct Current Electric Generator

Commutator

The commutator is a key component that helps convert AC voltage to DC voltage within the armature winding.

It's designed with a copper segment, which plays a crucial role in this process.

Each copper segment is protected from the other with the help of mica sheets, preventing any electrical issues.

The commutator is located on the shaft of the machine, making it a vital part of the overall mechanism.

Separately Excited

In a separately excited generator, the field coils are energized from an independent exterior DC source.

This means the field coils get their power from an external source, not from the generator itself.

The field coils are energized separately from the main generator operation, allowing for more control over the generator's output.

This type of excitation is often used in applications where a high degree of control over the generator's output is necessary.

Types of DC Generators

A DC generator is a type of electrical machine that converts mechanical energy into direct current (DC) electricity. It's a crucial component in many industries, including power plants and transportation systems.

The DC generator can be classified into two main categories as separately excited and self-excited.

In a separately excited DC generator, an external DC source is used to excite the field windings. This type of excitation allows for more control over the output voltage.

Self-excited DC generators, on the other hand, generate their own magnetic field through the use of a portion of the generated voltage.

Theory and Working Principle

Faraday's Law states that a changing magnetic flux on a looped conductor will produce a magnetic force that causes the electrons in the conductor to move, creating an electric current.

This fundamental principle is the underlying mechanism of electrical generators, and it's what makes DC generators work. The magnetic force applied to the electrons creates an electromotive force, which drives the electrons in the electric circuit.

The strength and direction of the electromotive force are determined by the strength and direction of the magnetic field and the velocity of the moving part of the generator.

In a DC generator, field coils produce an electromagnetic field, and the armature conductors are rotated into the field, generating an electromagnetically induced emf in the armature conductors. The direction of induced current is given by Fleming's right hand rule.

For more insights, see: Does Electric Turbo Work

Self Excited

Self Excited generators are a type of generator that energize their field coils from the generated current within the generator.

These generators are further classified into series wound, shunt wound, and compound wound types.

A key characteristic of self-excited generators is that they don't require an external power source to energize their field coils.

The series wound type of self-excited generator is one where the field coils are connected in series with the armature.

The shunt wound type is where the field coils are connected in parallel with the armature.

Compound wound generators have a combination of series and shunt wound field coils.

Consider reading: Shunt Generator

Working Principle

Faraday's Law states that a changing magnetic flux on a looped conductor will produce a magnetic force that causes the electrons in the conductor to move, creating an electric current.

The magnetic force applied to the electrons creates what is known as an electromotive force, and that is what drives the electrons in the electric circuit.

An electromotive force, or emf, gets induced in a conductor whenever it's placed in a varying magnetic field or moved in a magnetic field.

The magnitude of induced emf can be calculated from the emf equation of a DC generator.

In a DC generator, field coils produce an electromagnetic field and the armature conductors are rotated into the field, generating an electromagnetically induced emf in the armature conductors.

The direction of induced current is given by Fleming's right hand rule, which states that the direction of induced current changes whenever the direction of motion of the conductor changes.

The direction of current in every armature conductor will be alternating, but with a split ring commutator, connections of the armature conductors get reversed when the current reversal occurs, resulting in unidirectional current at the terminals.

Frequently Asked Questions

Why are solid pole shoes used in DC generators?

Solid pole shoes are used in DC generators to enlarge the armature core area, allowing for a larger induced emf. This is achieved through a specific shape that also supports the field coils.

Featured Images: pexels.com