A motor grader is a heavy-duty machine used in construction and road maintenance to grade or level surfaces. It's a versatile piece of equipment with a long history dating back to the early 20th century.

The first motor graders were introduced in the 1920s, and since then, they've undergone significant design improvements. One key feature of modern motor graders is their ability to perform multiple tasks, such as grading, leveling, and even snow removal.

Motor graders typically feature a large, flat blade that can be angled and adjusted to suit different terrain and tasks. This blade is attached to a rotating head that allows for precise control and maneuverability.

A different take: Motor Grader Blade

What is a Motor Grader?

A motor grader is a heavy machinery vehicle used in construction and road maintenance to move and level large amounts of soil, gravel, and sand.

It's equipped with a long blade or "grader" that can be angled and raised to perform various tasks, such as grading roads, excavating, and backfilling.

Definition

A motor grader is a piece of heavy equipment used for grading and leveling surfaces. It's typically used to reshape the surface of roads, cutting high spots and filling in low areas.

The motor grader is equipped with a variety of features, including an enclosed cab, heater, defroster, and lights, which are essential for comfortable and safe operation. This is particularly important in harsh weather conditions.

A motor grader must also be equipped with a slope meter, mounted inside the cab, to ensure accurate measurements. This helps operators get the job done efficiently and effectively.

In addition to these features, a motor grader must display a flashing light, visible from front and rear, and a "Slow Moving Vehicle" sign, visible from the rear, while operating. This is crucial for safety reasons.

Here are some key specifications for a motor grader:

- Must be tandem axle equipped

- Must be delivered with 1 complete additional set of OEM air and fluid filters

Parts of a Motor Grader

A motor grader is a large piece of equipment with a unique shape. It's made up of several key components that work together to help you grade and level surfaces.

The operator's cab is where you'll find the controls, levers, and steering wheel. A windshield and large windows enclose the cab, giving you a clear view of your surroundings.

The moldboard is the grader's working equipment, typically 12 or 14 feet in length. It has a cutting edge attached to the bottom and end bits on the sides, allowing it to be rotated 360 degrees in either direction.

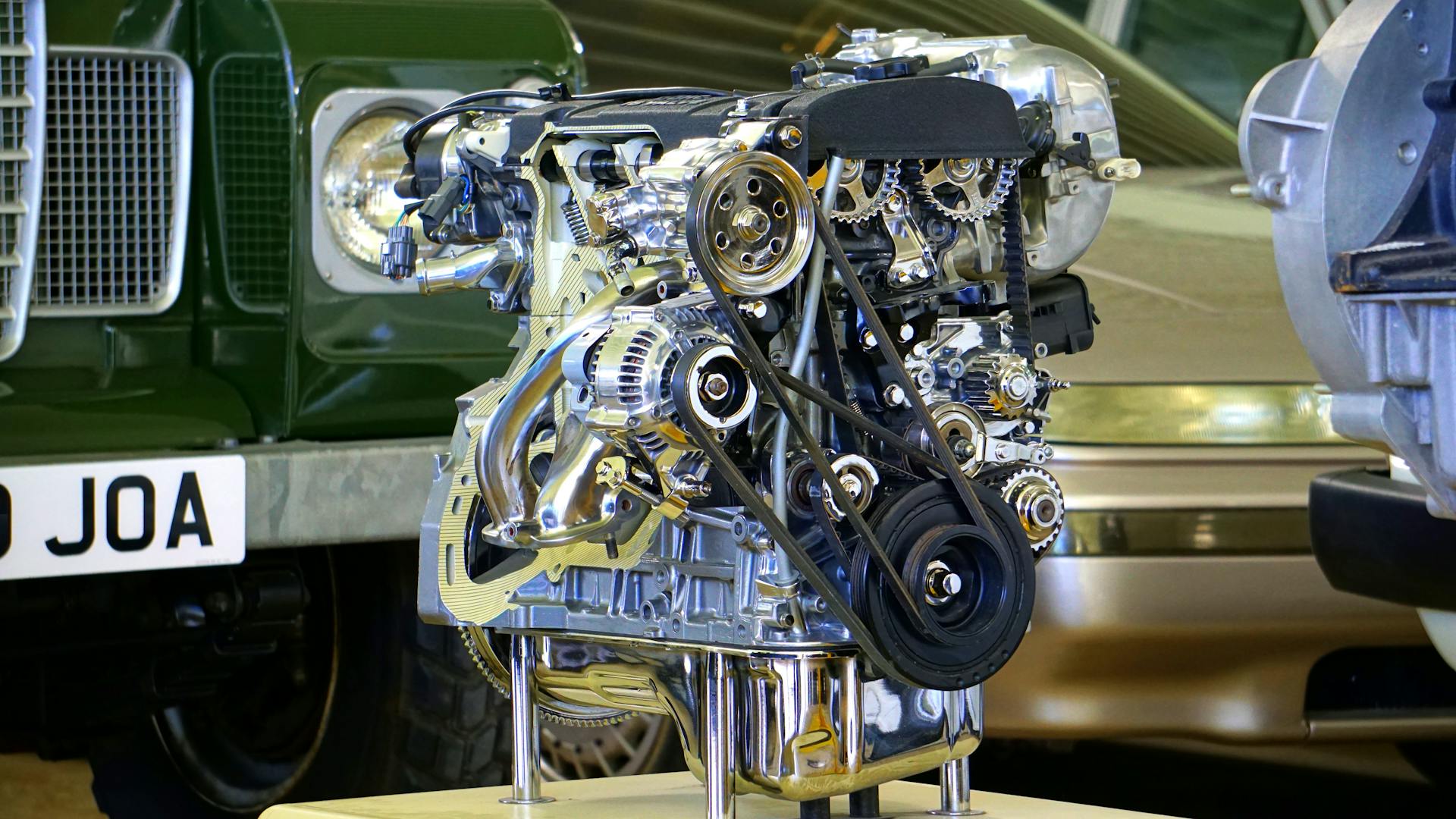

The prime mover is the rubber-tired tractor-mounted at the rear, powered by a diesel engine. This is what gives the motor grader its power and mobility.

The frame is connected to the front axle and extends the full length of the grader. Its height allows enough room for the moldboard to do its job.

The scarifier is located in front of or behind the front wheels and is hydraulically controlled. It uses teeth to break up compacted surfaces, making it easier to grade and level.

Here are the main components of a motor grader:

- Operator's cab

- Moldboard

- Prime mover

- Frame

- Scarifier

Types of Motor Graders

Motor graders come in three main sizes: large, medium, and small. Large motor graders are used for big projects like mining and constructing large buildings.

The largest motor graders are actually smaller than they used to be, with some units providing up to 249 HP. They're still quite powerful, but not as massive as their predecessors, which measured over 7.3 meters long and weighed 181,437 kilograms.

Medium motor graders have longer blades and larger wheels, making them perfect for public works like streets and highways. They're also great for large construction sites and hard-packed locations that need more power.

Small road graders have the least power, with units offering 145 to 190 HP, but they're ideal for small-scale projects and tight spaces. They're also great for unpaved roads and can easily navigate areas with limited space.

A unique perspective: Can a Ac Motor Be Used as a Generator

Rigid Frame

Rigid Frame motor graders have a fixed, non-articulating frame, making them ideal for straightforward grading tasks where flexibility is less critical.

Their design offers straightforward construction and robustness. This design is perfect for projects where you need a reliable machine that can get the job done without any fuss.

The new series in the market can detect any bounce effect and stabilize itself within a span of 15% speed adjustments. This feature is a game-changer for projects that require precision and accuracy.

Rigid Frame motor graders are a vital equipment in any construction site, executing a variety of activities with ease. They're perfect for producing flat surfaces on unpaved roads and creating smooth surfaces in paved roads for laying of asphalt.

Their ability to produce smooth surfaces is a must-have for any construction project.

Articulated Frame

An articulated frame is a common design feature found in motor graders, allowing for a wider range of motion and improved maneuverability. This type of frame is typically found in larger graders.

The articulated joint enables the machine to pivot around a central point, making it easier to navigate tight spaces and steep slopes. This is particularly useful in construction and excavation projects where terrain can be unpredictable.

In an articulated frame, the front and rear sections of the grader are connected by a hinge, allowing for a smooth and controlled movement. This design also helps to reduce the stress on the machine's components.

The articulated frame design is often used in motor graders that need to perform in challenging environments, such as on uneven or rocky terrain. This design feature is a key factor in the grader's ability to work effectively in these conditions.

Different Types of Motor Graders

Motor graders come in different sizes, including large, medium, and small units. Large motor graders are also called heavy motor graders and are used for large-scale projects like mining and constructing large residential complexes.

The largest motor graders today are much smaller, with some units providing up to 249 HP. They're proportionally larger than other graders and may require additional steps for operators to enter the cab.

Medium motor graders have longer blades and larger wheels, making them suitable for public works like streets, highways, and roads. They can also be used for large construction sites and hard-packed locations that need more power than a small grader.

Small road graders have the least power, with units offering 145 to 190 HP, and are ideal for small-scale projects that don't require extremely high power or extensive reach. They're also great for navigating tight spaces.

Articulated frame graders are used for large-scale projects and have two wheels larger than the others, attached to their own steering wheel. This allows for better maneuverability in narrow spaces, giving the operator more control over the two wheels.

Construction and Roadwork

A motor grader is a versatile machine used in various construction and roadwork projects. It's essentially a heavy-duty tool that helps create smooth, flat surfaces.

In road construction, motor graders are used to fine grade the base course, ensuring it's level and prepared for paving. They're also employed to create and maintain dirt roads, gravel roads, and asphalt roads. The machine's moldboard or blade can be hydraulically manipulated to complete a variety of tasks.

Motor graders play a crucial role in roadwork, as they help create a stable base for paved roads. They're used to prepare the uppermost layer for asphalt laying, and their ability to drive over roads without needing to haul between job sites makes them efficient.

A motor grader's applications in roadwork include highways, streets, and parking lots. They help flatten and smooth surfaces before workers can lay asphalt.

Some of the advantages of using a motor grader in roadwork include:

- Fast and efficient performance

- Precise capabilities cause less disturbance to the soil

- Articulated frame graders can maneuver in tight spaces

- Can drive over roads and do not need to haul between job sites

- Great for larger projects

In construction, motor graders are used to level surfaces for placing building foundations. They're also used to create inclines, drainage ditches, and to remove snow.

Here are some of the tasks a motor grader can perform:

- Create the base for paved roads

- Set the foundation for a large building

- Create inclines

- Create drainage ditches

- Remove snow

- Mix and spread materials

- Finish grading

- Ditch cutting

- Scarifying

- High bank cutting

Motor Grader Options and Selection

If you're in the market for a motor grader, you've got several options to consider. Large graders offer the most power, ideal for highly-compacted debris or ground that's difficult to penetrate and level.

When it comes to maneuverability, smaller graders have the most, making them perfect for small construction sites where navigation is more important than powerful grading. Large graders, on the other hand, are best operated in significant project sites, as they can be challenging to navigate in narrow areas.

Consider the following factors to select the right motor grader for your needs:

What Are My Options?

So, you're looking for a motor grader that fits your needs. You've got several options to choose from, and I'm here to help you break it down.

Large graders are ideal for highly-compacted debris or ground that's difficult to penetrate and level. They offer the most power, making them perfect for large-scale construction projects like condominiums, high-rise towers, and large complexes.

Medium graders have a high amount of power, but are best suited for medium-sized tasks. They're great for roads and highways, offering the best level of reach.

Small graders have the least power, but are best used where maneuverability is more important than having more power. They're perfect for small construction sites, small streets, and unpaved areas.

Rigid frame graders are used best for everyday types of grading, and are a good choice for the agricultural industry. Articulated frame graders, on the other hand, offer more maneuverability despite their size, making them best for larger projects that require more control and maneuverability while having more reach.

Here's a quick rundown of the different types of graders and their best uses:

Now, take a closer look at each type of grader and see which one fits your needs best.

Bulldozer Selection

If you're looking to choose a bulldozer, consider its intended use. For smaller or medium-sized projects in construction, mining, land clearing, and forestry, a bulldozer is a good fit.

When working on rough terrain, a bulldozer's capabilities shine. They're designed to push large amounts of material, making them ideal for this type of task.

For another approach, see: D9 Bulldozer Specs

To determine the right bulldozer for your needs, consider the scope of your project. For smaller projects, a bulldozer will be sufficient, but for larger projects, a motor grader may be a better choice.

Here are some key characteristics of bulldozers to keep in mind:

- Push large amounts of material

- Work on rough terrain

- Used for smaller or medium-sized projects in construction, mining, land clearing, and forestry

Manufacturer Overviews

John Deere Motor Graders are equipped with advanced technology features that boost efficiency and productivity. Their SmartGrade equipment features in-cylinder position sensing to match the articulation angle, blade pitch or circle offset selected by the operator.

The John Deere Efficiency Manager uses automation to match and adjust the performance of the engine and transmission to ground speed. This helps operators achieve more in less time.

Some notable improvements in John Deere Motor Graders include ejector scraper enhancements with a 15% larger gate opening, and optimized vertical pin adapters for quick attachment sleeves. These features make operations smoother and more efficient.

Here are some key features of the John Deere Automation Suite:

- Blade flip: automatically flips the blade for more efficient grading.

- Auto-articulation: automatically adjusts the articulation angle for optimal grading.

- Operator selectable presets: allows operators to save and recall custom settings for different grading tasks.

Cat Overview

Caterpillar has been a leader in the motor grader field since 1903. They're the world market leader for premium solutions with integrated productivity tools, comfortable cabs, and advanced electronics and hydraulics.

Their motor graders are designed with operator comfort in mind, featuring advanced air suspension seats, air conditioning, and heat temperature control. This helps reduce operator fatigue.

Cat motor graders also offer improved lines of sight for safer operation. You can even equip your grader with a radio and phone charger for added convenience.

Cat Grade with Cross Slope technology provides auto-control on one side of the blade, while the operator controls the opposite side. This feature is a game-changer for precise grading.

Some motor graders can also equip 3D grade and slope control via third-party technology providers. This takes grading to a whole new level of accuracy.

The Stable Blade option senses machine bouncing and takes steps to prevent it automatically. This feature is a must-have for anyone who's experienced the frustration of machine bouncing.

A unique perspective: Cat 415 Skip Loader

Auto articulation is another innovative feature that allows the grader to articulate automatically with steering input. This makes operation smoother and more efficient.

Here are some key features of Cat motor graders:

- Ergonomics: advanced comfort with air suspension seats, air conditioning, and heat temperature control

- Auto-control: Cat Grade with Cross Slope technology

- Machine bounce prevention: Stable Blade option

- Auto articulation: automatic steering input

John Deere Overview

John Deere is a well-known manufacturer that has been making significant improvements to their equipment. John Deere SmartGrade equipment features in-cylinder position sensing to match the articulation angle, blade pitch or circle offset selected by the operator.

One of the notable features of John Deere's motor graders is the ejector scraper improvements. John Deere offers ejector scraper improvements with a 15% larger gate opening that boosts shielding and material ejection.

The company has also optimized their quick attachment system. Optimized vertical pin adapters improve usability for quick attachment sleeves with short and long drawbars.

John Deere's Efficiency Manager is another innovative feature. The John Deere Efficiency Manager uses automation to match and adjust the performance of the engine and transmission to ground speed.

A different take: John Deere 210 Trackhoe

The Automation Suite is a comprehensive system that helps operators by reducing common control tasks. The John Deere Automation Suite helps operators by reducing common control tasks with blade flip, auto-articulation and operator selectable presets.

Here are some key features of John Deere's motor graders:

- Ejector scrapers with 15% larger gate opening for improved shielding and material ejection

- Optimized quick attachment system with improved usability for short and long drawbars

- Efficiency Manager for automated engine and transmission performance

- Automation Suite for reduced common control tasks

Frequently Asked Questions

Is it hard to operate a motor grader?

Operating a motor grader requires some understanding of the equipment and experience, but it's not unusually difficult to learn. With the right training, you can master the operation of a motor grader.

What is the function of a motor grade?

Motor graders smooth and even out road surfaces, ensuring a safe and durable road for transportation. They play a key role in maintaining road integrity over time.

What is the difference between grader and motor grader?

A grader and a motor grader are essentially the same machine, with "grader" being a more general term and "motor grader" emphasizing its heavy-duty, engine-powered design.

Featured Images: pexels.com