A jib boom crane is a versatile and efficient piece of equipment that can be used for a variety of tasks, from construction to manufacturing.

There are several design options to choose from, including fixed jib cranes, slewing jib cranes, and pendant jib cranes.

Each type of crane has its own unique benefits and is suited for specific applications.

Design and Components

A jib boom crane's design and components are surprisingly straightforward. The basic design is simple, requiring less maintenance compared to other types of cranes.

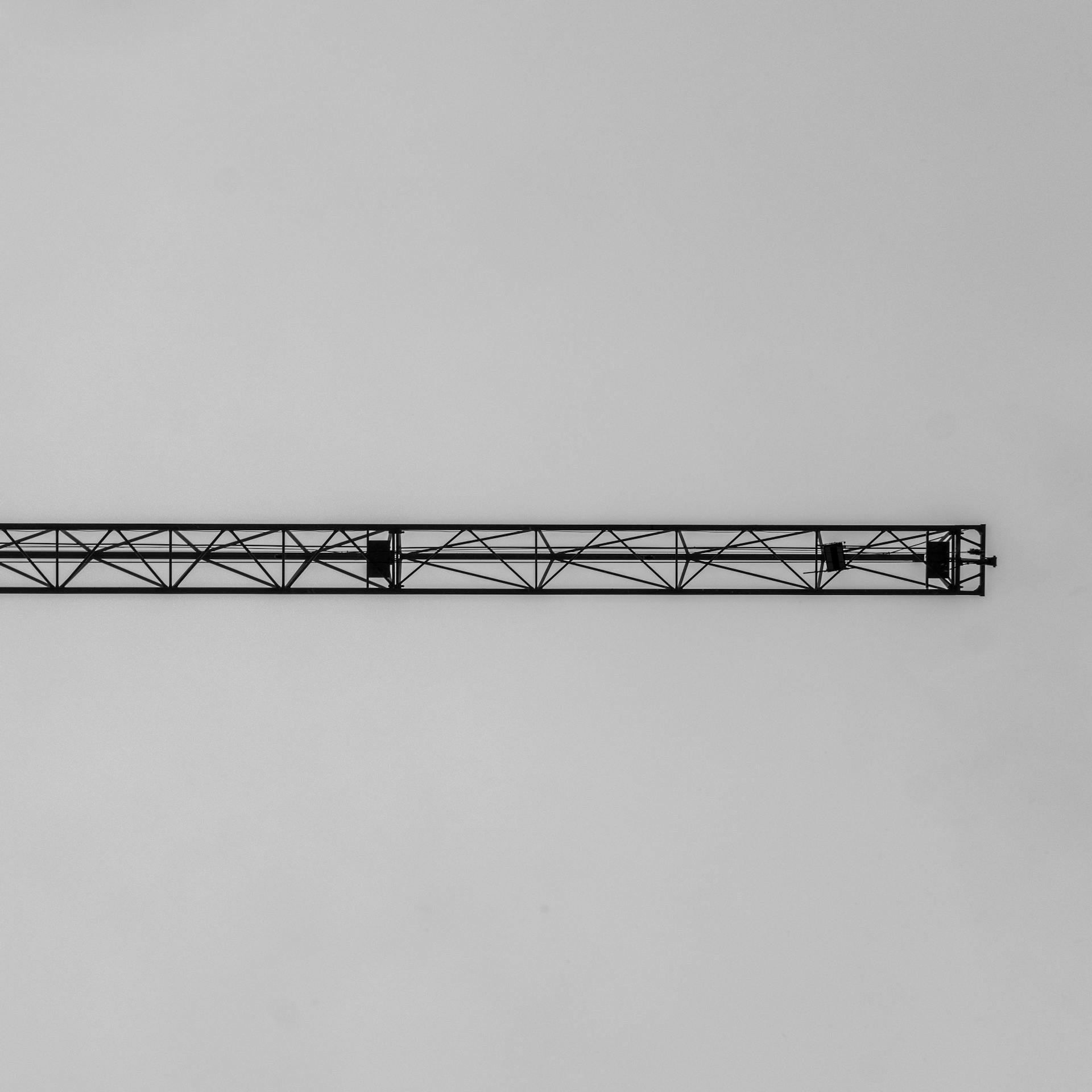

The main components of a jib system include the reach/boom, mast/pillar, movable hoist, trolley, and rotation. The reach/boom is the horizontal beam that the trolley travels back and forth on, while the mast/pillar supports the boom on freestanding and mast systems.

The trolley carries the hoist, wire rope or chain, and the hook along the entire length of the boom, with the motion of the trolley being manual, motorized, or pneumatic. Rotation is possible on freestanding and mast type jib cranes, achieving 360° of boom rotation, while wall and column-mounted jib cranes can achieve 180-200° of rotation.

Curious to learn more? Check out: Jib Crane Design Drawings

Here are the main components of a jib system:

- Reach/Boom – the horizontal beam that the trolley travels back and forth on.

- Mast/Pillar – the vertical beam used to support the boom on freestanding and mast systems

- Movable Hoist – the hoist is used to lift, position, and lower a load.

- Trolley – the motion of the trolley can be manual, motorized, or pneumatic.

Components

A jib crane's components are actually quite straightforward. The main parts include the reach/boom, mast/pillar, movable hoist, trolley, and hook.

The reach/boom is the horizontal beam that the trolley travels back and forth on. This is where the magic happens, and the crane can lift heavy loads with ease.

The mast/pillar is the vertical beam that supports the boom on freestanding and mast systems. It's a crucial part that keeps the crane stable and secure.

The movable hoist is used to lift, position, and lower a load. It's typically carried by the trolley, which moves along the boom.

The trolley can be manual, motorized, or pneumatic, and it carries the hoist, wire rope or chain, and the hook along the entire length of the boom. This is what allows the crane to lift loads with precision.

On freestanding and mast type jib cranes, you can achieve 360° of boom rotation. On wall and column-mounted jib cranes, you can achieve 180-200° of rotation.

Consider reading: Pillar Jib Crane

You can add electrification/pneumatic power to the top or bottom of the mast to provide rotation assistance and allow for continuous 360° boom rotation.

The controls on motorized or air-powered jib systems can be as simple as a push button controller to control the rotation of the boom, as well as the motion of the trolley and the lifting and lowering motion of the hoist.

Here are the main components of a jib crane in a list for easy reference:

- Reach/Boom

- Mast/Pillar

- Movable Hoist

- Trolley

- Rotation (360° or 180-200°)

- Electrification/Pneumatic Power

- Controls

The hook height of a jib crane is also an important consideration. You'll need to know the lowest overhead obstruction to determine how tall your jib crane can be.

A rotation stop can be added to limit the crane's motion before it collides with a nearby object, especially if it's located close to a wall or other obstruction.

For outdoor applications, the components of the jib system can be galvanized to resist corrosion. This is a great option if you're planning to use your crane in harsh environments.

Mast Type

Mast type jib cranes are a cost-effective alternative to freestanding systems. They don't require a special foundation, just 6” of reinforced concrete to support the crane.

Typically, mast type jib cranes can accommodate spans of 10-40 feet, capacities up to 10 tons, 360° rotation, and boom heights up to 40 feet. These cranes are similar to freestanding systems and can be used for heavy-duty/high-productivity applications.

There are two types of cantilever design options: Full Cantilever and Drop Cantilever. The Full Cantilever design is used when there are no overhead obstructions, while the Drop Cantilever design allows for clearance for overhead obstructions located below the top of the mast.

Mast type jib cranes can be mounted to the building's floor and steel beams, providing full 360-degree rotation. This setup is highly versatile and can be used in various industrial applications.

American Equipment offers mast type jib cranes in full cantilever and drop cantilever jib crane styles. Their mast style jib cranes are available with standard lifting capacities ranging from 0.25 to 5 tons, heights up to 20 feet, and spans up to 20 feet.

Here are the key specifications of mast type jib cranes:

- 10-40’ spans

- Capacities up to 10 tons

- 360° rotation

- Boom heights up to 40’

Types of Systems

There are several types of jib crane systems available, each with its own range of capabilities and design options.

Mast type jib cranes are a cost-effective alternative to freestanding systems, requiring only 6” of reinforced concrete to support the crane. They can accommodate spans of 10-40’, capacities up to 10 tons, and 360° rotation, with boom heights up to 40’.

Articulating jib cranes have two swivel arms that can lift loads around corners and columns, and reach into or under machinery and containers. They offer a greater coverage area and more flexibility closer to the mast or column.

Mast type jib cranes can be used for heavy-duty/high-productivity applications, but they do require an overhead beam or support structure to provide support in addition to the foundation.

Here are some key differences between mast type and articulating jib cranes:

Installation Options

When choosing a jib boom crane installation option, consider the space and structural requirements of your facility.

Freestanding jib cranes can be installed virtually anywhere, including indoors or outdoors, and can accommodate spans up to 50' and capacities up to 15 tons.

There are three main designs for freestanding jib cranes: Base-Plate Mounted, Foundation/Insert Mounted, and Sleeve-Insert Mounted.

These designs vary in terms of how they can be mounted and installed, but all offer flexibility and customization options to suit your needs.

The following table outlines the main characteristics of each design:

Wall-mounted jib cranes, on the other hand, offer space-saving benefits and can be installed close to ceilings or walls, but may require structural engineering approval prior to installation.

Free Standing

Free standing jib cranes offer the flexibility of being installed virtually anywhere, with no placement limitations. They can be used in open areas or small workstations, indoors or outdoors.

Freestanding jib cranes can accommodate spans up to 50 feet and capacities up to 15 tons. They also offer 360 degrees of rotation and boom heights up to 40 feet.

There are three main designs for freestanding jib cranes: Base-Plate Mounted, Foundation/Insert Mounted, and Sleeve-Insert Mounted. Each design has its own advantages and can be used depending on the specific needs of the installation.

The Base-Plate Mounted design is the easiest to install and the most popular, but it requires a reinforced concrete foundation. The Foundation/Insert Mounted design eliminates the need for gussets, while the Sleeve-Insert Mounted design allows for relocation of the jib system without damaging the mast.

Free standing jib cranes can be used underneath bridge cranes or in open areas where the crane can serve several workstations. They help make the most out of available space, improving efficiency and increasing productivity throughout a facility.

Here are some specifications of free standing jib cranes:

- Standard 0.25 to 5 ton lifting capacity

- Standard 8 to 20 feet spans

- Top or bottom entry for 360° boom rotation

- Optional power rotation

Foundationless jib cranes are another type of freestanding jib crane that can be installed almost anywhere in a facility. They are slab-mounted and bolted to 6″ reinforced concrete for indoor use.

Wall-Mounted

Wall-mounted jib cranes are a great space-saving option for factories and warehouses. They can be installed very close to the underside of the lowest ceiling obstruction, providing maximum clearance both under and above the boom.

These systems can be designed to swing around obstacles, under obstructions, or fold out of the way of overhead cranes to ensure no interruption of production. A wall-mounted cantilever jib crane offers the greatest amount of clearance, above and below the boom, and has a full-cantilever design.

Wall or column-mounted jib cranes can accommodate spans ranging from 8-30 feet and capacities up to 5 tons. They can also rotate 180°-200°.

Wall-mounted jib cranes can be designed to mount to a wall or building support column in two different ways: cantilever or tie-rod supported. The tie-rod supported design is the most economical means of providing hoist coverage along walls or building columns.

Here are some key specifications for wall-mounted jib cranes:

- Spans: 8-30 feet

- Capacities: up to 5 tons

- Rotation: 180°-200°

These types of jib systems are among the most economical in price and design, but they do have some limitations, including not allowing for full 360° of rotation.

Benefits and Applications

Jib boom cranes offer several advantages for your operations, including cost savings for mounting and maximized space utilization.

One of the most significant benefits of jib boom cranes is enhanced worker productivity. By streamlining lifting operations and reducing the need for manual labor, you can free up your team to focus on more important tasks.

Jib boom cranes can be used in a variety of settings, including production environments and outdoor locations. They're particularly well-suited for repetitive lifting in small work areas.

In addition to these benefits, jib boom cranes also offer improved safety and reduced risk of workplace injuries. This is due in part to their simple operation and fewer maintenance requirements.

Here are some of the key benefits of jib boom cranes at a glance:

- Cost savings for mounting

- Maximized space utilization

- Enhanced worker productivity

- Reduced risk of workplace injuries

- Improved safety

- Simple operation

- Fewer maintenance requirements

Features and Options

Our jib boom crane is designed with several key features that make it a reliable and efficient choice for various applications. It's offshore rated, meaning it can withstand harsh marine environments.

One of the standout features of our crane is its continuous slewing, which allows for smooth and precise movement. This is especially useful in situations where precision is crucial.

The crane's maximum capacity at a wide range of outreaches is another notable feature. This means that you can lift heavy loads from a variety of distances, making it perfect for projects with complex lifting requirements.

The crane's optimised weight/capacity ratio also ensures that it's easy to transport and set up, reducing downtime and increasing productivity. This is a major advantage for projects with limited space or tight deadlines.

Some of the available options for our crane include remote control and an operator's cabin. These features make it easy to operate the crane safely and efficiently, even in challenging environments.

Centralised Greasing System

Heila marine cranes have greasing points on all pins and pivot points to keep them operating efficiently and prevent excessive wear.

A Manual Central Greasing System can be installed to simplify maintenance and extend the crane's service life.

If you want to take it a step further, a programmable Automatic Central Greasing System can be installed to grease the crane automatically, with no risk or human intervention.

Led Floodlight

LED floodlights can be fitted to the tip of the crane's boom to illuminate the working area around the crane.

We offer swivelling or fixed lighting solutions with power outputs ranging from 100 to 1000 equivalent wattage (W).

Load and Radius

Our marine cranes feature a range of load and radius indicators that can be customized to meet your specific needs. These indicators can be displayed on portable remote units or video screens installed in operator control stations or operator cabins.

The indicators provide a clear and accurate picture of the loads and their corresponding radii, helping to ensure safe and efficient operations.

Specific indicators are available depending on the application and in agreement with the customer. We can equip the crane with a visual indication of the loads and 3D controls.

Here's a summary of the load and radius indicators:

- Available on portable remote units or video screens

- Installed in operator control stations or operator cabins

- Can be customized to meet specific application needs

- Provide visual indication of loads and 3D controls

Alarms

Alarms are a crucial feature for safe and reliable crane operation. Acoustic and visual alarms can be installed on cranes to alert operators of potential hazards.

A green/yellow/red light is typically installed on the crane column, indicating the 90%/100%/110% SWL load on the crane.

Acoustic alarms can be paired with visual alarms to provide an additional warning system. This combination is mandatory for use on fully IACS certified cranes.

Integrated Pulley System

Heila's integrated pulley system is a game-changer for lifting loads with a winch.

To lift loads with a winch, a different solution is required than with a fixed hook. Heila offers a solution by integrating a pulley head or top sheave into the last boom extension.

This allows for single line pull or multiple line pull solutions according to the customer's needs.

Hoisting Winches

Heila winches come in a wide range of capacities, from a single line pulling capacity of 500 kg up to more than 50 metric tonnes.

The winches have multiple speeds to suit different tasks and requirements. Heila winches are designed to meet customer needs, with options for multiple drum rope capacities.

All Heila winches are equipped with an electric/hydraulic load limiter to control the pulling force on the rope and prevent the exceedance of the maximum safe working load. This ensures safe operation and prevents accidents.

The winches are fitted with non-rotating, galvanized and greased steel cables.

Frequently Asked Questions

What is a jib boom on a crane?

A jib boom is a rotating support on a crane that holds the power, hoist, and other equipment, allowing for flexible movement and handling of loads around obstacles. It typically attaches to the mast or wall of the crane, providing a crucial component for efficient crane operation.

What is the difference between a jib crane and a boom crane?

A jib crane extends reach and tackles tasks requiring exceptional height or distance, whereas a boom crane provides primary reach for lifting tasks. The addition of a jib to a boom crane enhances its capabilities, making it a valuable asset in various projects.

Featured Images: pexels.com