Electric turbo compressor technology is a game-changer for industries that rely on compressed air. It uses an electric motor to drive a compressor, which is more efficient and environmentally friendly than traditional diesel-powered compressors.

The electric turbo compressor is a type of oil-free compressor that uses a turbine to compress air. This design reduces energy consumption and maintenance costs.

Compared to traditional compressors, electric turbo compressors can save up to 60% of energy costs. This is because they use advanced technologies like variable speed drives and energy recovery systems.

In addition to energy savings, electric turbo compressors are also quieter and produce less vibration than traditional compressors. This makes them ideal for applications where noise and vibration are a concern.

What Is Etc?

So, what is ETC? ETC stands for Electric Turbo Compressor. In the context of electric turbo compressors, ETC is a key component that plays a crucial role in the system.

ETC uses electric motors to drive the compressor, which is a significant departure from traditional turbo compressors that rely on internal combustion engines.

The ETC's electric motor eliminates the need for a traditional engine, reducing emissions and increasing efficiency.

The compressor itself is a critical part of the ETC system, responsible for compressing air or gas to the desired pressure.

The ETC system can be used in a variety of applications, including industrial processes and power generation.

In an ETC system, the compressor is typically connected to an electric motor via a gearbox or other mechanical component.

The ETC's ability to provide high-pressure compressed air or gas makes it an attractive option for applications that require precise control.

Compressor Types and Features

There are two main types of compressors for fuel cell systems: positive displacement type and turbo type.

The turbo type, specifically centrifugal compressors, are considered the most efficient solution for fuel cell air supply systems.

IHI, a company with over 20 years of experience, uses centrifugal compressors as the air supply source for its fuel cell systems.

What Are Turbochargers?

Turbochargers are a type of compressor that uses exhaust gases to spin a turbine, which in turn drives the compressor to force air into the engine.

There are two kinds of electric turbos currently in existence, the e-booster and the one-unit e-turbo made by Garret Motion.

The e-booster is a turbo that's essentially just a compressor side paired with an electric motor, used side by side with exhaust-driven turbos.

Garret Motion's e-turbo is a turbo paired with a motor, providing a low-end boost that turns off once exhaust pressure builds up.

The main difference between the e-booster and the e-turbo is that the e-turbo allows for the use of a larger compressor for smaller engine displacement.

Electric turbos use an electric motor and an electric compressor, eliminating turbo lag and providing quick low-end response.

Compressor Types for FC Systems

Compressor Types for FC Systems are primarily classified into two types: positive displacement and turbo type.

IHI specifically uses centrifugal (turbo) compressors as the air supply source for its fuel cell systems, which are considered the most efficient solution based on over 20 years of experience.

Centrifugal compressors are a type of turbo compressor.

IHI Features

IHI ETC machines offer a unique solution for oil contamination on the fuel cell (FC) stack. This is a significant advantage in certain applications.

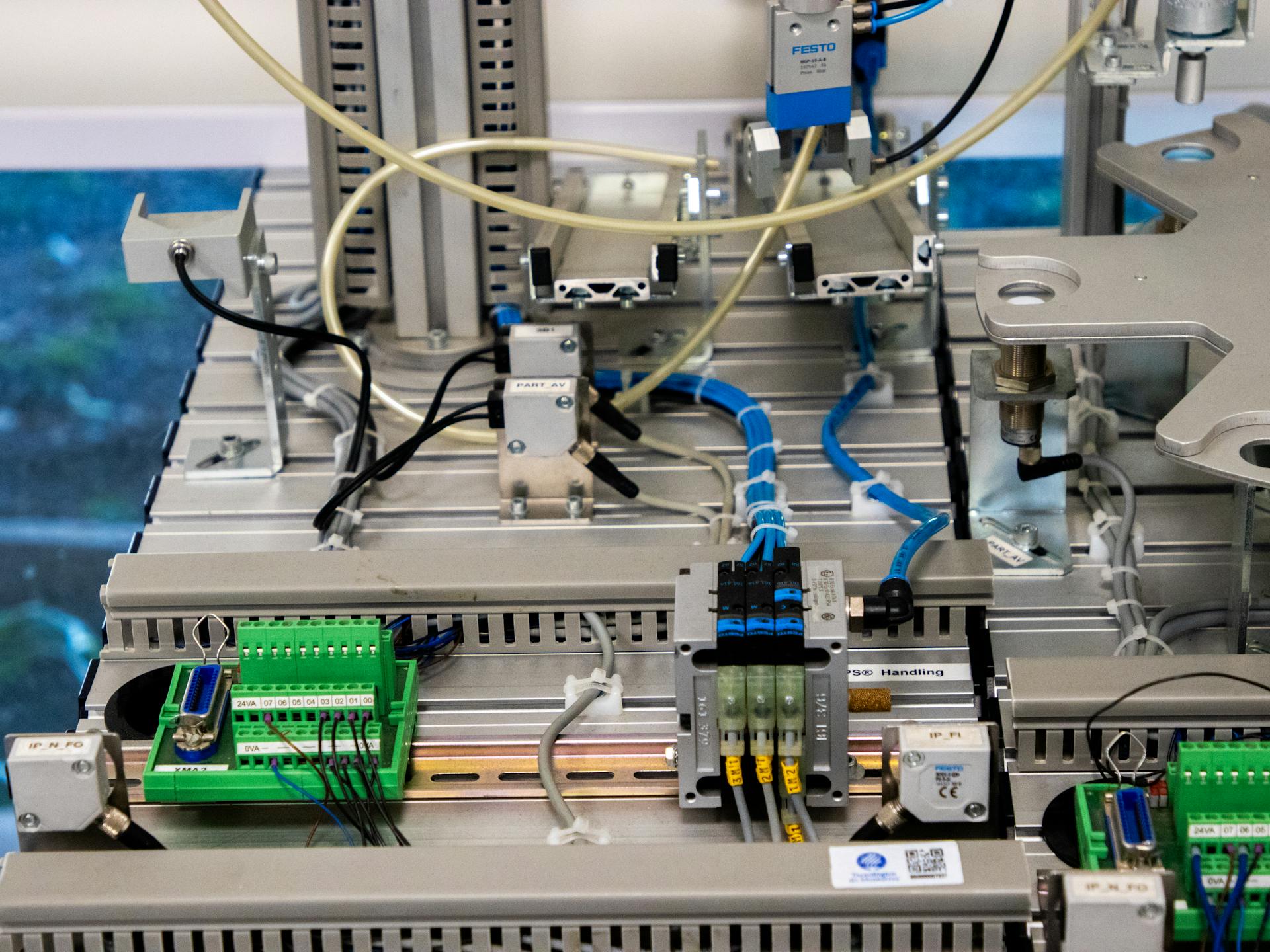

One of the standout features of IHI ETC is its mechatronic integration structure, which enables miniaturization by integrating the motor and inverter. This results in a more compact design.

The electrical compressor with turbine assist in IHI ETC is a game-changer. It recovers energy exhausted from the FC stack and provides 30% of the power required to drive the compressor, allowing for downsized and less power consumption ETC.

IHI ETC is designed for automotive use and can handle start-stop operation for fuel-efficient driving modes. This is a key feature for vehicles that need to optimize fuel efficiency.

IHI ETC has achieved a significant improvement in power density, with a 58% increase from their first ETC model introduced in the market. This is a testament to their successful downsizing of the inverter.

IHI Series Lineup

IHI offers a range of compressor products, known as the ETC series, which cater to different fuel cell system output requirements.

The ETC series lineup includes sizes from S to L, with varying motor output powers of 11kW, 20kW, and 30kW respectively.

The ETC-S has a motor output power of 11kW, while the ETC-M 100 and ETC-M 150 have motor output powers of 20kW and 30kW respectively.

The ETC-L has a turbine power of 9kW, with a maximum speed of 90,000rpm.

Here's a breakdown of the ETC lineup:

The ETC series can handle high transient specifications, with the ETC-S taking 1.3 seconds to reach 90% of its maximum speed, and the ETC-L taking less than 2 seconds.

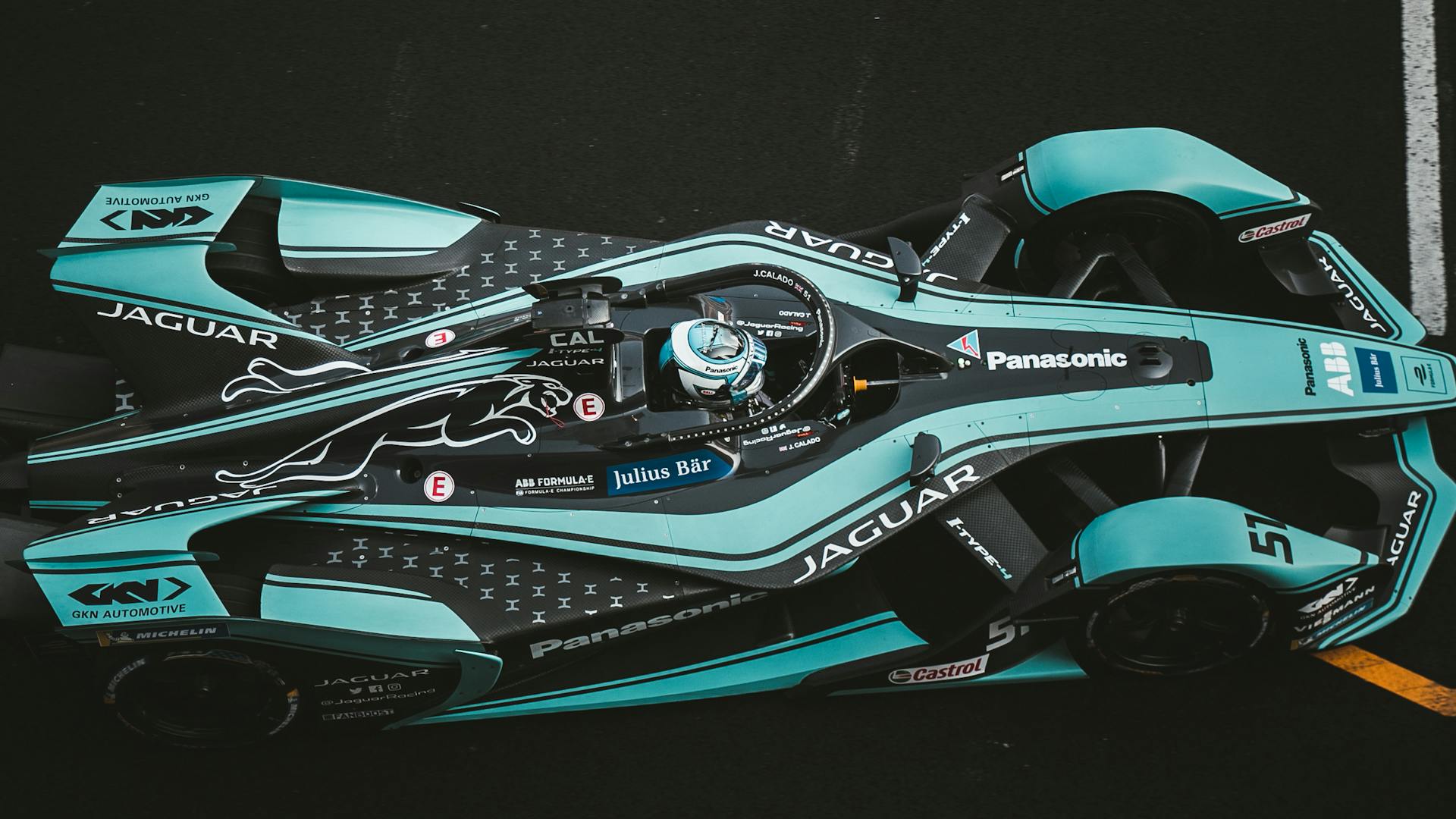

Porsche Turbocharger

Porsche's electric turbocharger is a game-changer in the world of car turbochargers. It uses electric motors to rotate the turbines, eliminating the need for kinetic energy from the engine.

The early version of car turbochargers used kinetic energy from the engine to rotate the motor, but Porsche's recent development is an electric turbocharger.

Readers also liked: Electric Turbo for Car

Porsche's electric turbocharger is a combination of an electric turbo with components and arrangements of a twin-turbo setup, making it capable of generating higher power similar to a big single turbo with the response and efficiency of two smaller turbos.

The independent working of turbines from the compressor enables them to rotate at different speeds, enhancing the operating ranges of each turbine and resulting in higher efficiency. This allows for a constant energy output, excluding the need for higher pressure.

The electric motors in Porsche's turbocharger provide instant energy to the compressor, independent of RPM, making it a major benefit. The bypass valve can be opened for enhanced economy, creating less stress on the engine while cruising.

Porsche's electric turbocharger exempted the turbo lag by using an innovative design, allowing for additional power and increased efficiency with no turbo lagging.

Consider reading: Electric Turbo Turbocharger

Frequently Asked Questions

Do electric turbochargers really work?

Yes, electric turbochargers are a real technology used in production cars, including those by major manufacturers like Audi

What are the disadvantages of electric turbochargers?

Electric turbochargers are currently expensive and their reliability is largely untested due to limited data and applications.

How fast does a turbo compressor wheel spin?

A turbocharger's compressor wheel can spin at speeds of up to 350,000 RPM, driven by the engine's exhaust gas. This incredible speed is what allows turbochargers to boost engine performance and efficiency.

Featured Images: pexels.com