A dc generator is a type of machine that converts mechanical energy into electrical energy in the form of direct current. The basic principle of a dc generator is based on the electromagnetic induction phenomenon.

The construction of a dc generator involves a stator and a rotor, with the stator typically consisting of a stationary magnetic field produced by a stator coil. The rotor, on the other hand, is a moving part that rotates within the stator's magnetic field.

What Is a DC Generator?

A DC generator is a type of electrical generator that produces direct current (DC) output.

It works on the principle of electromagnetic induction, where a rotating magnetic field induces a voltage in the conductor.

The DC generator consists of a rotating armature and a stationary magnetic field.

The armature is made up of a coil of wire, called the armature coil, which is attached to a rotor.

The magnetic field is produced by a stator, which is a stationary electromagnet.

The DC generator can be connected in series or parallel to increase the voltage and current output.

In a series connection, the voltage and current are increased, while in a parallel connection, the voltage remains the same but the current is increased.

The DC generator is widely used in applications where a stable DC output is required, such as in power supplies and motor control systems.

Consider reading: Direct Current Electric Generator

DC Generator Components

A DC generator is made up of several key components that work together to convert mechanical energy into electrical energy. The stator is the stationary part of the generator and is responsible for creating the magnetic fields where the coil spins.

The stator consists of two magnets with opposite polarities facing each other, positioned throughout the rotor's circumference. These magnets are crucial in generating the magnetic fields needed for the generator to produce electricity.

The rotor, on the other hand, is the moving part of the generator and is made up of slotted iron laminations that are stacked to form a cylindrical armature core. This design helps to minimize the loss caused by eddy current.

Armature windings are connected in series to parallel to increase the sum of produced current in a closed circuit. This is done to enhance the overall efficiency of the generator.

The commutator is a critical component of the DC generator, acting as a rectifier to convert AC electricity to DC voltage within the armature winding. It's designed with a copper segment, and each copper segment is protected from the other with the help of mica sheets.

Here's a breakdown of the main components of a DC generator:

The brushes are used to ensure that the electrical connections between the commutator and the outside load circuit are maintained. The pole shoe is used to disperse the magnetic flux and keep the field coil from dropping.

Working Principle

A DC generator operates on the principle of Faraday’s laws of electromagnetic induction.

According to Faraday’s law, an electromotive force (EMF) is induced in a conductor when it is placed in a fluctuating magnetic field or moved in a magnetic field. This law is the foundation of how a DC generator works.

The direction of the induced current is given by Fleming’s right-hand rule, which states that the direction of the current changes as the direction of movement of the conductor changes.

As the armature rotates, the direction of the current in the conductors will be alternating, with the current reversing direction every half rotation.

However, with a split ring commutator, the connections of the armature conductors get reversed when the current reversal occurs, resulting in a unidirectional current at the terminals.

The magnitude of the induced EMF can be calculated using the emf equation of the DC generator, which takes into account the number of turns of the coil, the area of the coil, and the magnetic field strength.

Fleming’s right-hand rule is essential in understanding the direction of the induced current in a DC generator, and it's a fundamental concept in electrical engineering.

Types and Construction

A DC generator is essentially a DC machine, which can be used as a motor or generator without any constructional changes. This is because the basic constructional details are the same for both DC generators and motors.

The DC machine consists of two main parts: the stator and the rotor. The stator includes the yoke, poles, and field winding, while the rotor includes the armature core and armature winding.

The stator's yoke is made of cast iron or steel and provides mechanical strength to the assembly, as well as carries the magnetic flux produced by the field winding. The poles are joined to the yoke and carry the field winding, while the pole shoes support the field coils and spread out the flux in the air gap uniformly.

The field winding is usually made of copper and is wound in a way that forms alternate North and South poles when energized. The armature core is the rotor of the DC machine, built up of thin laminated circular steel disks to reduce eddy current losses, and may be provided with air ducts for cooling purposes.

The armature winding is usually a former wound copper coil resting in armature slots, insulated from each other and the armature core. It can be wound using lap winding or wave winding, with double layer lap or wave windings being generally used.

For more insights, see: How Is a Shunt Wound Dc Generator Connected

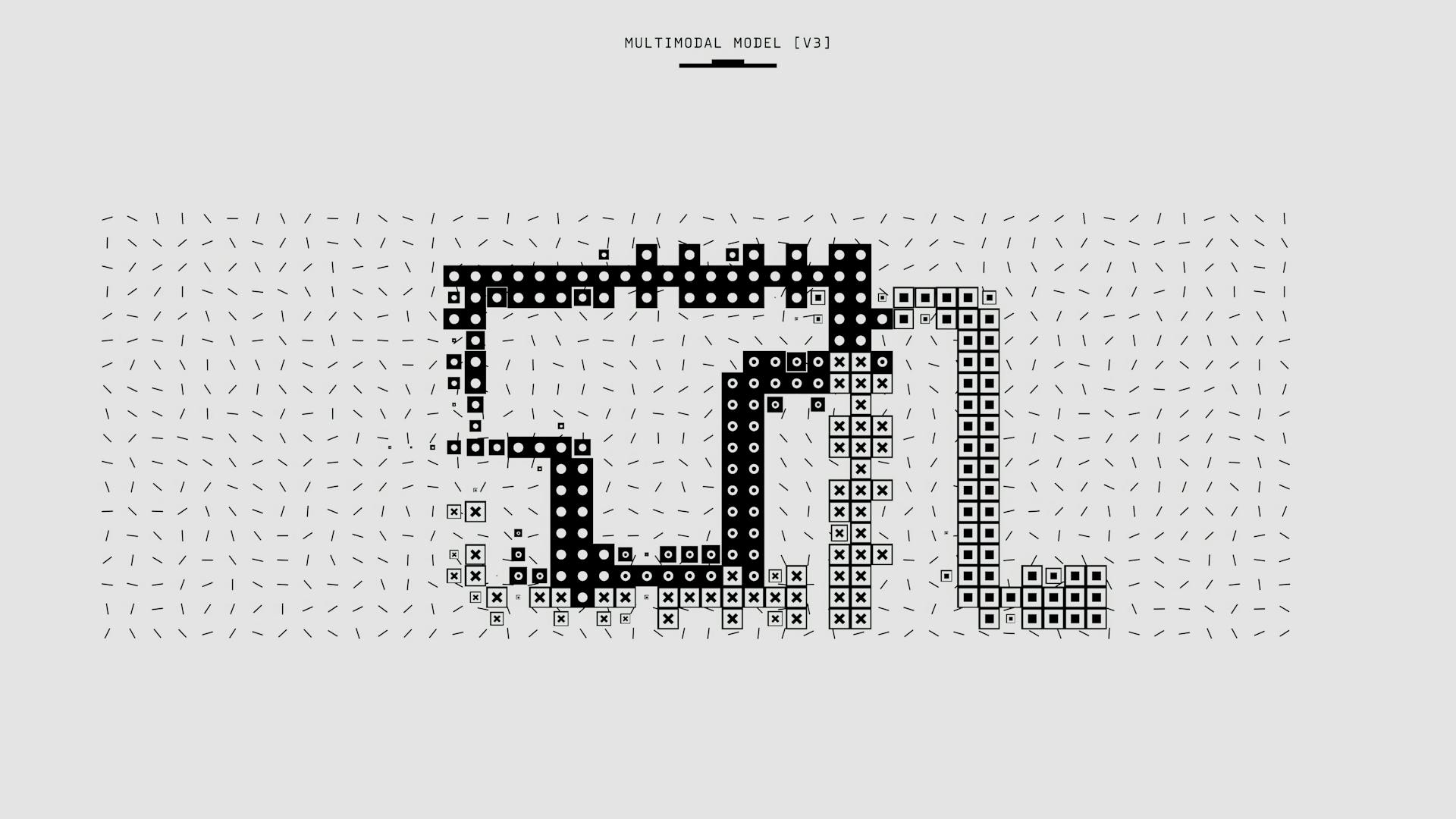

Diagram

A diagram is a crucial tool for understanding the construction of different types of structures. It helps visualize the relationships between various components.

For example, a diagram of a simple beam can show how it distributes loads evenly across its length. This is important for designing safe and stable buildings.

In a diagram of a suspension bridge, you can see how the cables and suspender cables work together to support the weight of the bridge. This is a key factor in its construction.

A diagram of a truss can illustrate how its triangular shape provides excellent strength and stability. This makes it a popular choice for building roofs and other structural elements.

By studying diagrams of different structures, you can gain a deeper understanding of their construction and how they work. This knowledge can be invaluable for architects, engineers, and builders.

For more insights, see: Ac Generator Diagram

Types of

There are two main categories of DC generators: separately excited and self-excited.

A separately excited DC generator has field coils that are energized from an independent exterior DC source.

Self-excited DC generators are a bit different, as their field coils are energized from the generated current within the generator.

Within the self-excited category, there are three main types of DC generators: Series Wound, Shunt Wound, and Compound Wound.

Here's a quick rundown of the three types:

- Series Wound Generators: energize the field coils in series with the armature.

- Shunt Wound Generators: energize the field coils in parallel with the armature.

- Compound Wound Generators: combine series and shunt connections to energize the field coils.

Machine Construction

A DC machine is made up of two main parts: the stator and the rotor. The stator is the outer frame of the machine, also known as the yoke, which is typically made of cast iron or steel.

The yoke provides mechanical strength and carries the magnetic flux produced by the field winding. It's a crucial component that holds everything together.

The rotor, on the other hand, is the armature core, which is cylindrical in shape with slots to carry armature winding. The armature core is built up of thin laminated circular steel disks to reduce eddy current losses.

The armature core may also be provided with air ducts for axial air flow to cool the machine. This is especially important when the machine is in operation.

A DC machine has several key components, including poles, pole shoes, field winding, armature core, armature winding, and a commutator and brushes. These components work together to make the machine function.

Here's a brief overview of each component:

- Poles and pole shoes: Poles are joined to the yoke and carry field winding, while pole shoes support the field coils and spread out the flux in the air gap.

- Field winding: Field coils are usually made of copper and are wound in a way that forms alternate North and South poles when energized.

- Armature core: The armature core is the rotor of the DC machine and is cylindrical in shape with slots to carry armature winding.

- Armature winding: Armature conductors are insulated from each other and the armature core, and can be wound using lap or wave winding methods.

- Commutator and brushes: The commutator collects or supplies current to the armature conductors, while brushes are made from carbon or graphite and rest on commutator segments.

The commutator and brushes play a crucial role in making physical connection to the armature winding. They help to collect or supply current to the armature conductors, depending on whether the machine is a generator or a motor.

Frequently Asked Questions

How to obtain DC current from a generator?

To obtain DC current from a generator, rotate a conductor within a magnetic field, inducing an electric current. This process is based on the fundamental principle of electromagnetic induction.

What is the rule of DC generator?

A DC generator operates based on Faraday's laws of electromagnetic induction, where a conductor induces an EMF in a fluctuating magnetic field. This fundamental principle enables the generation of direct current.

Sources

Featured Images: pexels.com