Baler machine agriculture is a game-changer for farmers, allowing them to efficiently harvest and process crops like hay, straw, and silage.

A baler machine can produce up to 1 ton of bales per hour, depending on the type of crop and machine used.

The process starts with the machine collecting and gathering the crop, then compressing and binding it into a neat bundle.

Farmers can choose from different types of balers, including small, portable units for small-scale farming and larger, more heavy-duty machines for commercial operations.

The compact bales produced by baler machines make them easier to store and transport, reducing labor costs and increasing efficiency.

By using a baler machine, farmers can save time and resources, allowing them to focus on other aspects of their business.

A unique perspective: Case Row Crop Tractor

Types of Baler Machines

There are several types of baler machines available, each with unique features and functionalities. The two most common types are the round baler and the square baler.

Related reading: Types of Tower Cranes

Round balers form cylindrical bales by continuously collecting and compressing crop material. They use a rotating chamber and rollers to gather the material, forming it into a compact cylindrical shape by applying intense pressure.

The finished bales are wrapped with twine or netting to maintain their shape and integrity. This is a crucial step to ensure the bales can be easily stored and transported.

Square balers, on the other hand, produce rectangular-shaped bales. They collect crop material into a chamber, compress it with plunger-like mechanisms, and finally tie the bales with twine or wire.

These specialized balers are designed to handle specific crops, such as corn stalks or cotton.

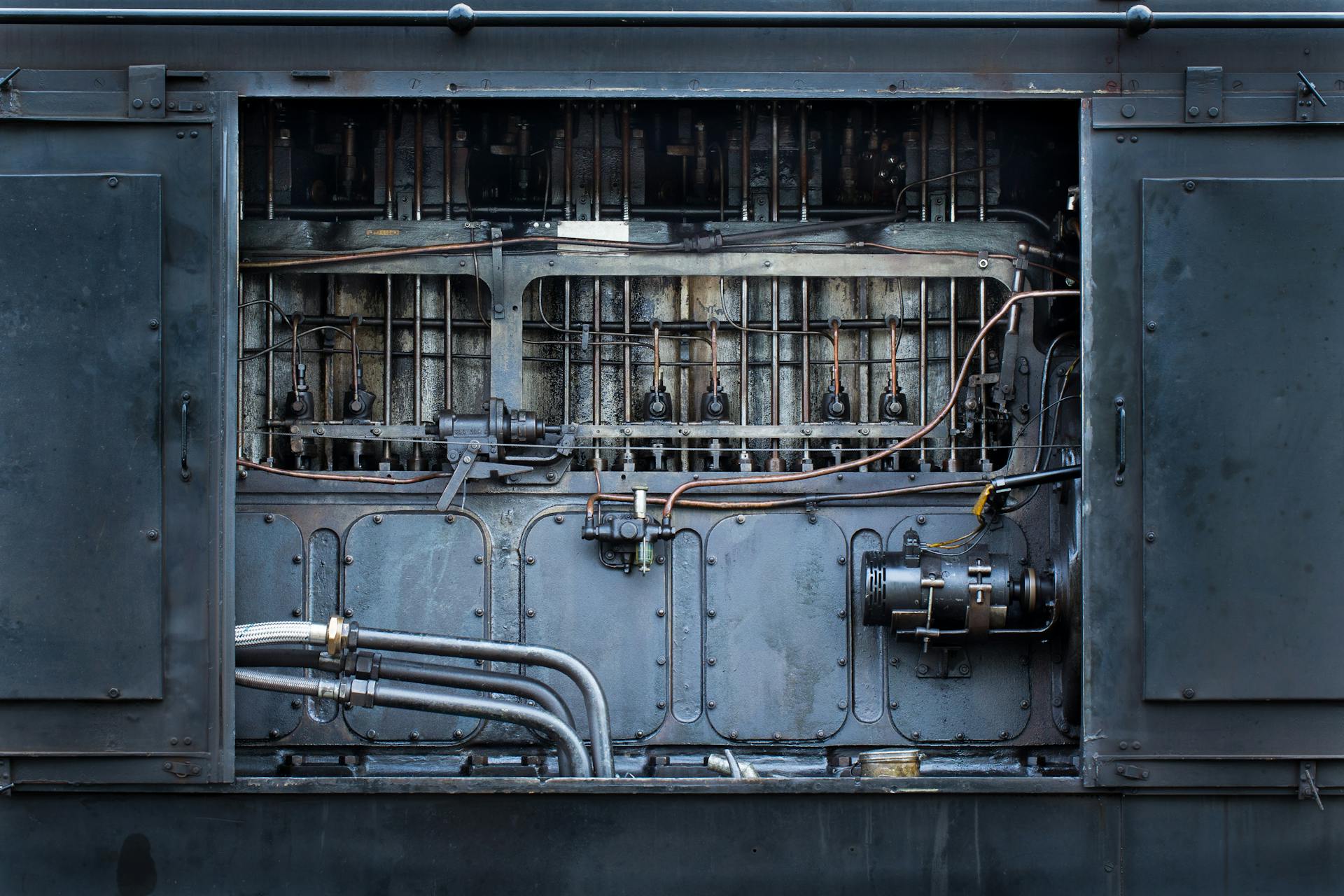

Components and Functioning

A baler machine is a crucial tool in agriculture, and understanding its components and functioning is essential for efficient baling. The baler machine consists of various components that work together to compress and bind agricultural materials.

The pickup component is responsible for collecting crop material from the ground or windrows, using a series of teeth or tines to lift and feed the material into the baler. This process is crucial for effective baling.

The rotating chamber or plunger is a key component in round balers, providing the necessary force to compress the crop material into tight bales. In square balers, the plunger plays a similar role, ensuring the crop material is compressed properly.

A tying system is used to secure the bales for storage and transport, with twine being a common method due to its cost-effectiveness. The baler machine also features a control system that allows operators to monitor and adjust various parameters during the baling process.

Mahindra Round

The Mahindra Round Baler is a high-performance machine that efficiently makes bales in the field.

It can form 60 to 80 bales per hour, allowing farmers to make more money in minimum time. This is a significant advantage for farmers who need to manage their time effectively.

The machine has a compact design with a length of 1740 MM, a width of 1550 MM, and a height of 1250 MM. This makes it easy to maneuver in tight spaces.

The bale weight can be 18 to 30 Kg, and the total weight of the mini Round Baler is 610 Kg to 625 Kg.

To operate this baler, you'll need a tractor with a power range of 35 to 45 HP. This is a relatively low power requirement compared to other balers on the market.

Here's a summary of the key specifications for the Mahindra Round Baler:

- Required Power – 35 to 45 HP

- Machine Weight – 610 Kg to 625 Kg

- Bale Dimensions – 610 x 1060 MM

- Pickup Width – 1175 MM to 1060 MM

Components of a

A baler machine consists of various components that work together to compress and bind agricultural materials.

The pickup component is responsible for collecting crop material from the ground or windrows, using a series of teeth or tines to lift and feed the material into the baler.

The rotating chamber or plunger is a key component in round balers, providing the necessary force to compress the crop material into tight bales.

In square balers, the plunger is crucial for compressing the crop material, just like in round balers.

A tying system is essential in balers, using methods like twine and wire-tying to secure the bales for storage and transport.

Twine is more commonly used in tying systems due to its cost-effectiveness.

A control system is also a vital component of a baler, allowing operators to monitor and adjust parameters during the baling process.

This enables operators to optimize the baling operation based on specific crop conditions.

Preparation and Operation

To operate a baler machine efficiently and safely, you need to prepare it properly first. This involves inspecting the baler to ensure all components are in good working condition.

Inspecting the baler is a crucial step, as it helps prevent accidents and ensures optimal performance. Check for any damages or wear and tear that may affect its operation.

Proper baler preparation also includes adjusting and lubricating the machine's components. This involves setting the tension of belts and chains, lubricating moving parts, and checking for proper alignment. Regular lubrication can help extend the life of the baler and prevent breakdowns.

To test the safety features of your baler, check the emergency stops and warning signals. These features are designed to protect the operator and prevent accidents.

Here are the key steps to prepare and operate a baler machine:

- Inspect the baler regularly to ensure all components are in good working condition.

- Adjust and lubricate the baler components to ensure smooth operation.

- Test the safety features, including emergency stops and warning signals.

Preparation

Preparation is key to safe and efficient operation of a baler. It's essential to inspect the baler thoroughly to ensure all components are in good working condition.

A thorough inspection involves checking for any damages or wear and tear that may affect the baler's operation. This includes looking for signs of rust, corrosion, or wear on moving parts.

Adjusting and lubricating the baler components is also crucial for smooth operation. This involves setting the tension of belts and chains, lubricating moving parts, and checking for proper alignment.

Testing safety features is another important step in baler preparation. This includes checking emergency stops, warning signals, and other safety devices to ensure they're functioning properly.

Here's a quick checklist to help you prepare your baler:

- Inspect the baler for any damages or wear and tear.

- Adjust and lubricate the baler components.

- Test safety features like emergency stops and warning signals.

Operation

Operating a baler requires some know-how to get the job done efficiently and safely. To start, position the baler in an optimal spot to collect the crop material.

The baler's pickup height or width needs to be adjusted according to the crop conditions to ensure efficient collection. This is a crucial step to prevent any issues during the baling process.

Feeding the material into the baler's chamber is the next step. Use the pickup mechanism to gather the crop material and maintain a steady material flow to keep the baling process smooth and continuous.

The baler's rotating chamber or plunger applies pressure to compact the crop material tightly. Optimize the compression by adjusting the settings based on the crop type and desired bale density.

Once the baling process is complete, the baler's tying system secures the bales to prevent them from coming apart. Adjust the tying system properly to maintain the integrity of the bales.

Here are the general steps involved in operating a baler:

- Positioning and Adjusting the Baler

- Feeding the Material

- Compacting the Material

- Tying the Bales

- Ejecting the Bales

Frequently Asked Questions

How much does a baler cost?

A vertical baler's upfront cost typically ranges from $5,000 to $20,000. Learn more about the factors that influence baler pricing and find the right one for your needs.

What is baling in agriculture?

Baling in agriculture is the process of compressing and wrapping crop into compact bundles, typically using a machine to pick up, compact, and wrap the crop into a bale. This efficient method helps farmers store and transport crops in a convenient and space-saving way.

What is a bailer in farming?

A baler is a farming machine that compresses hay or straw into tightly packed bales, typically weighing between 22-45 kg. It uses a pickup mechanism to collect and process the material into rectangular or cylindrical bales.

Sources

- https://dergipark.org.tr/en/pub/bsagriculture/issue/82826/1401132

- https://www.sinobaler.com/hay-baler-machine-revolutionizing-the-farming-industry/

- https://www.tractorjunction.com/blog/best-baler-machine-for-agriculture/

- https://makinhay.com/how-the-vermeer-round-baler-changed-the-agriculture-industry/

- https://barnyardtools.com/baler-in-agriculture-how-it-works-its-use/

Featured Images: pexels.com