Asynchronous generators are a great choice for renewable energy projects, especially for wind turbines, where they can operate at variable speeds. They're also more cost-effective and require less maintenance than synchronous generators.

In fact, asynchronous generators can produce power at speeds between 500 and 1800 RPM, making them ideal for applications where speed variability is a given. This flexibility is a major advantage in the field of renewable energy.

However, synchronous generators are still a popular choice for certain applications, such as hydroelectric power plants, where they can operate at a fixed speed and provide a stable power output. They're also more efficient at high power levels.

Discover more: Electric Motor Synchronous Speed

Working Principle

The working principle of asynchronous generators, also known as induction generators, is based on electromagnetic induction.

The slip, which is the difference between the synchronous speed and the speed of the rotor, is a key concept in understanding how induction generators work. Slip is calculated as (Ns – N)/Ns, where Ns is the synchronous speed and N is the speed of the rotor.

You might like: Motor Synchronous Speed Formula

The synchronous speed depends only on the supply frequency and the number of poles, and it's the speed of the stator's revolving magnetic field. A four-pole motor running on a 60 Hz grid has a synchronous speed of 1800 rotations per minute.

The slip can be positive, zero, or negative, depending on the rotor speed. When the slip is positive, the rotor tries to catch up to the synchronous speed and generates torque, making it operate as an induction motor.

In an induction generator, the slip is negative, which means the rotor speed is higher than the synchronous speed. This occurs when the rotor is driven by a prime mover, such as a turbine or engine, and the machine delivers power to the electrical load.

The stator flux induces currents in the rotor, which creates a rotor flux with the opposite magnetic polarity of the stator. This causes the rotor to be pulled behind the stator flux, and an active current is generated in the stator coils, making the motor operate as a generator.

Related reading: Homopolar Motor Generator

Types of Generators

There are several types of generators, including AC and DC generators. AC generators are further classified into alternators or synchronous generators and asynchronous (induction) generators.

AC generators are used to convert mechanical energy into electrical energy, with the stator providing output electrical power to a given circuit. The rotor is driven by a prime mover, such as a water turbine or wind turbine.

The main types of generators are:

- Alternator or Synchronous Generator

- Asynchronous (Induction) Generator

These types of generators are used in various applications, including power generation and distribution.

Generator

A generator is essentially an electrical machine that converts mechanical energy into electrical energy. The mechanical power to the rotor of the machine is provided using a prime mover such as a water turbine, steam turbine, wind turbine, etc.

Generators are classified into AC and DC generators. The AC generator is further classified into alternator or synchronous generator and asynchronous (induction) generator.

The stator and rotor are two key components of a generator. The stator is used to provide output electrical power to a given circuit.

A generator's output can be provided using the stator, which is a crucial part of the machine.

Readers also liked: Examples of Electrical Generators

Types

Generators come in various types to suit different needs and applications.

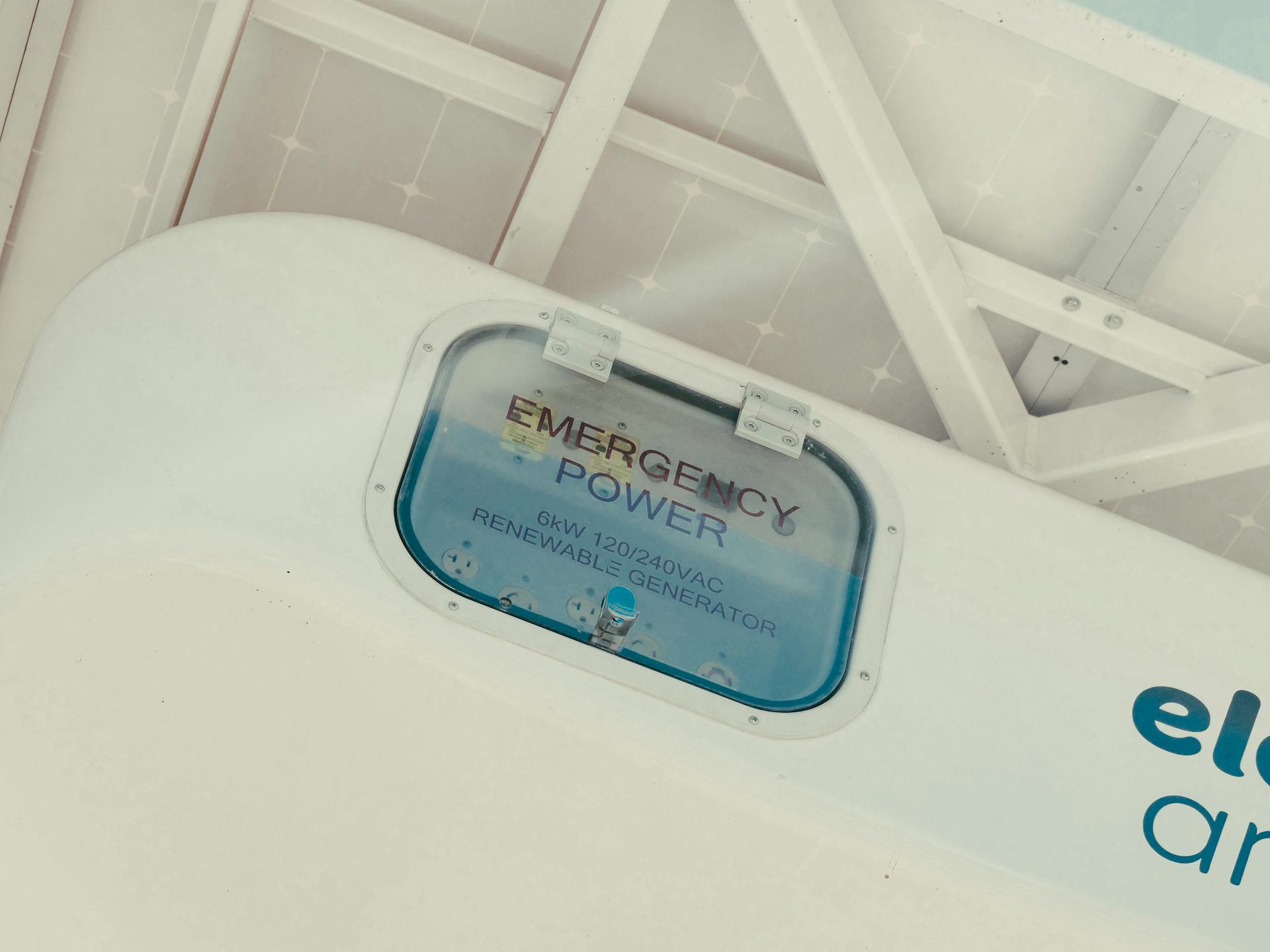

Portable generators are a popular choice for camping, tailgating, and emergency power. They're usually small, lightweight, and easy to transport.

Home standby generators are designed to provide backup power during outages, keeping your home's essentials running. They're typically installed outside and connected to your home's electrical system.

Inverter generators are known for their quiet operation and fuel efficiency, making them ideal for RVs, boats, and small construction sites.

Diesel generators are often used in heavy-duty applications, such as construction, mining, and industrial settings, due to their high power output and durability.

Natural gas generators run on a clean-burning fuel source, reducing emissions and operating costs. They're commonly used in residential and commercial settings.

Related reading: Inverter Dual Fuel Generator

Doubly Fed

Doubly Fed Generators are a type of induction generator that offers flexibility in speed and power output. They use a wound-type rotor with slip rings, allowing for external control of the rotor current. This control enables reactive power compensation and provides a constant output power even in variable speed conditions.

The rotor is electrically accessible, and the generator includes a back-to-back converter that converts AC power into DC and back into AC. This converter setup allows for adjustable amplitude and frequency of the delivered power.

A DC link capacitor is placed between the two converters, acting as a DC voltage source. This setup is commonly used in wind turbines and hydroelectric power plants where the operating speed is variable.

The stator is directly connected to the grid, while the rotor is connected through a back-to-back converter controlled by the prime mover. This design enables the generator to maintain a constant amplitude and frequency of the delivering power at variable speed.

For your interest: Thermo Generator Setup

Grid Connection

The grid connection of an asynchronous generator, specifically a Grid Connected Induction Generator (GCIG), is a crucial aspect of its operation. It relies on the grid to provide the necessary reactive power for stator excitation.

The stator of a GCIG is connected to the grid, which generates the rotating magnetic field in the stator. This setup allows the generator to work in parallel with the electrical grid.

A control system is used to synchronize the GCIG with the grid, ensuring its output frequency and phase match the grid's frequency and phase.

Expand your knowledge: 3 Phase Ac Generator

Grid Connected

Grid Connected systems are designed to work in harmony with the electrical grid.

The Grid Connected Induction Generator (GCIG) is a type of system that works in parallel with the grid, providing necessary reactive power for stator excitation.

It's commonly used in renewable energy sources like hydroelectric power stations and wind turbines.

The stator of a GCIG is connected to the grid, which generates the rotating magnetic field.

A squirrel cage rotor is used, connected to a prime mover that rotates the rotor.

The rotor's speed must increase above the synchronous speed to start delivering power to the grid.

Since it's directly connected to the grid, synchronization is crucial before power generation begins.

A control system is used to synchronize the GCIG with the grid.

Power Protection Relay

Power protection relays are a crucial aspect of grid connection, particularly when it comes to induction generators.

One of the main types of power protection relays used is the Reverse Power Protection Relay, which senses the direction of power flow and breaks the circuit when power flows in the reverse direction.

This is necessary because induction generators draw power instead of delivering it when they operate as a motor.

The relay helps to disconnect the power to the induction generator when it starts operating as a motor, preventing damage to the system.

A key feature of power protection relays is their ability to prevent under/over speed conditions that can cause over-excitation.

The under/over speed relay disconnects the capacitors to prevent uncontrolled voltage generation due to over-excitation.

Here are some key facts about power protection relays:

- They are used to prevent induction generators from operating as motors.

- They disconnect power to the induction generator in case of reverse power flow.

- They prevent under/over speed conditions that can cause over-excitation.

Self-Excited

A self-excited induction generator is a type of asynchronous generator that doesn't require an external power source to operate. It uses a capacitor bank to provide the necessary reactive power for excitation.

The capacitor bank is connected in delta configuration across the stator's terminals, allowing the machine to operate without a grid connection. This makes it ideal for small-scale power plants.

A capacitor bank can also be connected to the stator terminals to supply reactive power to the machine as well as the load. This setup enables the induction generator to supply the load without using an external source.

The rotor must be rotated at sufficient speed to induce a voltage across the stator's terminals, and a small voltage is generated due to residual magnetism. This generated voltage is enough to create a capacitor current that provides more reactive power for magnetization.

For more insights, see: Induction Generator

Advantages and Disadvantages

An asynchronous generator, also known as an induction generator, has several advantages that make it a popular choice for certain applications.

It does not require synchronization with the main supply line, which simplifies the installation process.

Its robust construction and reduced maintenance needs make it a low-maintenance option.

Asynchronous generators have a higher energy density, meaning they can produce more power relative to their size.

The speed of the prime mover does not impact the performance of an asynchronous generator.

They can also operate in parallel, making them suitable for larger power generation systems.

On the other hand, asynchronous generators have some disadvantages to consider.

A lower relative cost compared to synchronous generators is one of the main advantages of asynchronous generators.

Take a look at this: Asynchronous Generator Python

Advantages and Disadvantages

An induction generator has some amazing advantages that make it a great option for certain applications. One of the biggest benefits is that it doesn't require synchronization with the main supply line.

It has a robust construction, which means it's built to last and requires less maintenance than some other types of generators. This can save you time and money in the long run.

Induction generators have a higher energy density, or in other words, they can produce more power relative to their size. This makes them a great choice for applications where space is limited.

The speed of the prime mover doesn't affect the performance of an induction generator, which is a big plus. This means you can use it with a variety of different engines or turbines.

One of the most convenient features of induction generators is that they can operate in parallel with each other. This makes it easy to scale up or down as needed.

They also have a lower relative cost compared to some other types of generators. This can be a big advantage if you're working on a budget.

Advantages of Three-Phase

Three-phase generators have several advantages that make them a popular choice for many applications. One of the key benefits is their low noise emissions.

These generators are designed to operate with load-independent rotation speeds, which means they can handle varying loads without affecting their performance. This is a significant advantage over other types of generators.

One of the most impressive features of three-phase asynchronous generators is their high level of reliability and ease of maintenance. This makes them a great choice for applications where downtime is not an option.

Here are some key features of three-phase asynchronous generators:

With their ability to operate at frequencies of 50 and 60 Hz, three-phase asynchronous generators are suitable for a wide range of applications.

Frequently Asked Questions

What is an asynchronous generator?

An asynchronous generator, also known as an induction generator, is a type of AC generator that uses induction motor principles to produce electric power. It operates by mechanically spinning its rotor faster than its synchronous speed.

What are the advantages of asynchronous generators?

Asynchronous generators offer several advantages, including not requiring voltage regulation and being suitable for variable wind speeds in wind power plants. They also provide a versatile option for various applications

Sources

- https://www.electricaltechnology.org/2024/04/induction-generator-asynchronous-generator.html

- https://mechanicaljungle.org/induction-generator-vs-synchronous-generator/

- https://www.kiwithinker.com/2017/05/generator-types-synchronous-versus-asynchronous-what-goes-on-inside-the-machines/

- https://www.menzel-motors.com/generators/

- https://deeptechzero.com/blog/asynchronous-vs-synchronous-generators-choosing-the-right-option-for-small-hydroelectric-plants/

Featured Images: pexels.com