What is a lot number? It's a unique identifier assigned by manufacturers to groups of products that were made at the same time, in the same place, and under the same conditions. This number helps companies track their inventory and maintain quality control. However, it also plays an essential role in protecting consumers from harmful products.

The Consumer Product Safety Commission requires manufacturers to include lot numbers on all consumer products they produce. In case of a product recall, manufacturers use this information to identify which items are affected and how they're handled. A product recall means retrieving, replacing, fixing, or reimbursing customers for the affected goods. Without adequate information like lot numbers, identifying these items becomes almost impossible. This not only raises costs for businesses but also damages their reputation and can lead to stock prices plummeting in worst-case scenarios.

Understanding lot numbers isn't just important for manufacturers' bottom line—it's also crucial for warehouse managers to avoid storing expired or recalled products inadvertently. That's why we've put together this quick guide on what lot numbers are and why they matter so much in today's marketplace.

Consider reading: John Deere Lawn Tractor Model Numbers Explained

Understanding Lot Numbers: Your Quick Guide

A lot number is a unique identifier assigned to a specific product during the manufacturing process. Lot numbers are used to track items and identify recalled items. You can find lot numbers on various products such as food, drugs, and even in the beverage industry.

Lot numbers are also known as batch numbers or the FDA registration number. Drug manufacturers use lot numbers to comply with regulations set by the Food and Drug Administration (FDA). The specific product's lot number usage varies depending on its purpose.

Expiration dates are usually associated with lot numbers. A happy batch manufacturing process means that all products from the same production run have the same expiration date. If you want to check if your product is part of a recall, you can use the lot number for identification purposes. If your download didn't start click here, but understanding lot numbers shouldn't be difficult after reading this quick guide!

For your interest: Ford Tractor Model Numbers

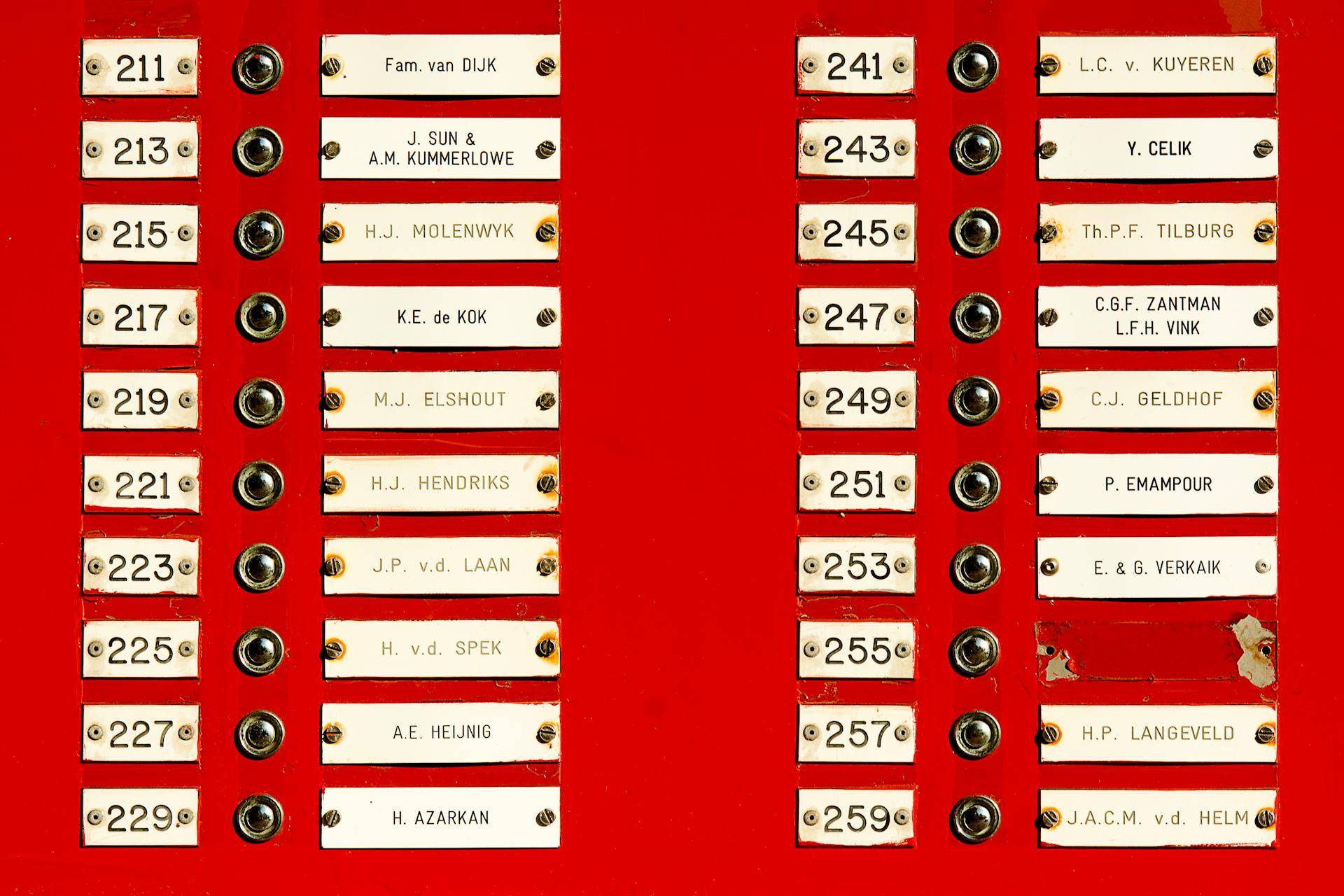

Discovering the Best Location for Your Product's Lot Number

A lot number is a unique identifier assigned to a specific batch of products during the manufacturing process. This number allows manufacturers and retailers to track products manufacturing information, including the date and location of production, and any other relevant data.

Alternatively, manufacturers may send components or raw materials to a contract manufacturer who will create the final product. In this scenario, it is essential that each component has its own lot number so that issues can be identified quickly if necessary.

It is standard practice to place lot number labels underneath each product or on the packaging, so they are easy to find at any stage of production or distribution. If an issue arises with a particular batch of products affected by a recall, it is essential to have a system in place to locate all items with that specific lot number quickly. Lot tracking software can help with this task and find integration with popular e-commerce and accounting software such as Quickbooks Online, Amazon FBA, or Shopify POS.

Consider reading: Lot Tracking in Manufacturing

Omnichannel inventory management guide for manufacturers

What is a lot number and why is it important in inventory management for manufacturing businesses? Lot numbers are unique identifiers assigned to a group of products that were produced at the same time and under the same conditions. These numbers allow manufacturers to track their inventory and trace any issues that may arise, such as defects or recalls.

In an omnichannel inventory management system, lot numbers play a crucial role in ensuring accuracy and efficiency. By assigning lot numbers to products, manufacturers can easily track their inventory across multiple sales channels and warehouses. This helps prevent overstocking or stockouts, which can harm a business's bottom line.

In fact, accurate inventory management is one of the top 10 challenges faced by manufacturing businesses today. By implementing lot numbers and other inventory tracking methods, manufacturers can stay on top of their inventory levels and streamline their operations. So if you're looking to improve your manufacturing business's inventory management system, don't overlook the importance of lot numbers.

Worth a look: Retail Inventory Management

Answering Your Question: What Exactly Is a Lot Number?

A lot number is an identification number assigned by a single manufacturer to a specific group of products. It is also known as a batch number, code number, or lot code. The lot number typically consists of numerical digits applicable to the specific group of products and won't change throughout their lifecycle.

The assigning of lot numbers is an important thing for manufacturers as it allows them to track and trace their products throughout the supply chain. Each product's lot number contains information about its manufacture location, expiration date, and other relevant details that help manufacturers pinpoint any issues that may arise during production. This helps in ensuring high-quality standards are maintained.

In summary, a lot number is a unique group of digits assigned by manufacturers to identify specific groups of products manufactured at one time in one place with similar specifications or characteristics. Understanding lot numbers is essential for tracking and tracing products through the supply chain and maintaining quality control standards. Keep an eye out for these important codes the next time you purchase goods!

Related reading: Quickbooks Online Lot Tracking

Why Incorporating a Lot Number Matters for Your Product

Lot numbers are essential in business inventory management techniques. Generally speaking, lot numbers are used to track what's going on with your products. When you're manufacturing pharmaceuticals or regulated products, lot numbers are typically required for traceability and quality control purposes. This is because these products need to be tracked from the raw materials stage all the way through the production process to ensure that they meet quality standards.

If you're selling perishable goods such as food products, using lot numbers makes sense. Adding expiration dates to your lot number application is good practice, as it ensures that you can monitor these goods' shelf life and take appropriate action when needed. Furthermore, if you're unsure about how long a particular item has been sitting on your shelf or in storage, err on the side of caution and start tracking lot numbers.

In addition to monitoring perishable goods, incorporating lot numbers can also be beneficial when handling goods through e-commerce inventory management software features such as batch tracking. By removing unnecessary data and adding missing data like lot numbers, you can make informed decisions regarding your inventory levels and supply chain management systems. This is especially important in industries where consumer electronics or beverages may depreciate overtime or have short shelf lives. So don't overlook this critical aspect of business inventory management – start using lot numbers today!

Here's an interesting read: John Deere Tractor Model Numbers

Should You be Using Lot Numbers for Your Products?

Lot numbers are commonly used in various industries, such as food and beverage, clothing, and drug manufacturing. They serve as a tool for product differentiation and can be used in common situations like a recall situation or when a clothing product comes in the wrong color or size. Lot numbers help to identify and handle products that have slight variations, ensuring that only high-quality, safe-to-consume products are sent out.

Expiration dates are crucial for food and drink products, but lot numbers can also be helpful in this case. With cloud-based technology, it's easy to track which lot number corresponds to which production date. This way, when a product expires, you know exactly which batch of items to throw away and order fresh products instead. Incorporating lot numbers into your quality assurance (QA) process is essential to test products thoroughly before they get released to the public.

Drug companies tend to use lot numbers because they're required by legal compliance from government organizations including the FDA. Lot tracking is necessary in case of defective items that need to be recalled. In conclusion, incorporating lot numbers into your business practices can help ensure that you produce high-quality products that comply with legal requirements while giving you peace of mind knowing that everything is traceable if something goes wrong.

1. Where Can I Find the Lot Number on Products?

If you're wondering where to find the lot number on a product, you're not alone. Lot numbers are important identification codes that manufacturers use to track batches of products. They help ensure quality control and traceability in case of any issues or recalls.

One common place to find the lot number is on the packaging or label of the product. It may be listed as "Lot #," "Batch #," or "Code #" followed by a series of letters and numbers. If you're having trouble finding it, try looking for other identifying information such as a product code or expiration date. You can also check the manufacturer's website or contact their customer service for assistance.

How to use lot tracking in manufacturing

Lot tracking is a method used in manufacturing to keep track of stock and inventory. It involves assigning a unique number, known as the lot number, to each batch of products or materials produced. In this article, you'll learn how lot tracking can help companies ensure that they don't sell faulty items or expired food, outdated goods, or any other products that may be harmful.

Lot traceability is crucial in ensuring that manufacturers comply with regulations and safety standards. By using lot tracking, businesses can quickly identify which batches of products are affected by a recall or quality issue. This makes it easier for them to take corrective action before any harm is done.

Using manufacturing software with built-in lot tracking functionality can streamline inventory management processes and reduce errors. The software can automatically assign lot numbers to new batches of materials or products as they come in and track their movement through the production process. This helps manufacturers identify potential bottlenecks or inefficiencies in their processes and make improvements where necessary. Overall, implementing lot tracking in inventory management is essential for ensuring product quality and safety while also improving operational efficiency.

Discover the Significance of Tracking Lot Numbers

In today's rapidly changing business environment lot numbers play a vital role in quality assurance and long-term sustainability. Lot control is especially important in highly regulated sectors such as pharmaceuticals, food industries and cosmetics. The ability to track products by lot number can be a competitive advantage for businesses, and it becomes even more critical during emergency situations. Emergencies lot control can quickly identify the exact batch of product arise so that it can be traced back to its source, allowing companies to conduct necessary recalls, reduce waste, and protect their brand reputation. Therefore, tracking lot numbers is crucial for ensuring product quality and safety while maintaining a competitive edge in the market.

Frequently Asked Questions

How to find lot numbers?

Lot numbers can typically be found on the packaging or label of a product, often near the expiration date or production date. If you are unable to locate the lot number, contact the manufacturer for assistance.

Can a lot number track where a product was made?

Yes, a lot number can track where a product was made as it identifies the specific batch or lot of products and includes information such as the manufacturing location and date.

What does "lot number" mean on a vehicle?

A lot number on a vehicle refers to the identification number assigned to a group of cars manufactured in the same batch at a particular time. It helps in tracking the production and distribution of vehicles.

What is the difference between lot numbers and serial numbers?

Lot numbers are used to identify a group of products that were manufactured together, while serial numbers are unique identifiers for individual products. This means that if there is an issue with a specific product, it can be traced back using its serial number, whereas issues with a lot of products can be tracked using the lot number.

What is a lot number?

A lot number is a unique identification code assigned to a specific batch or lot of a product during the manufacturing process. It helps track and trace the product in case of any issues or recalls.

Featured Images: pexels.com