Gen sets are a reliable source of power, especially for applications that require constant energy. They can operate in parallel with the grid, providing prime power and backup power.

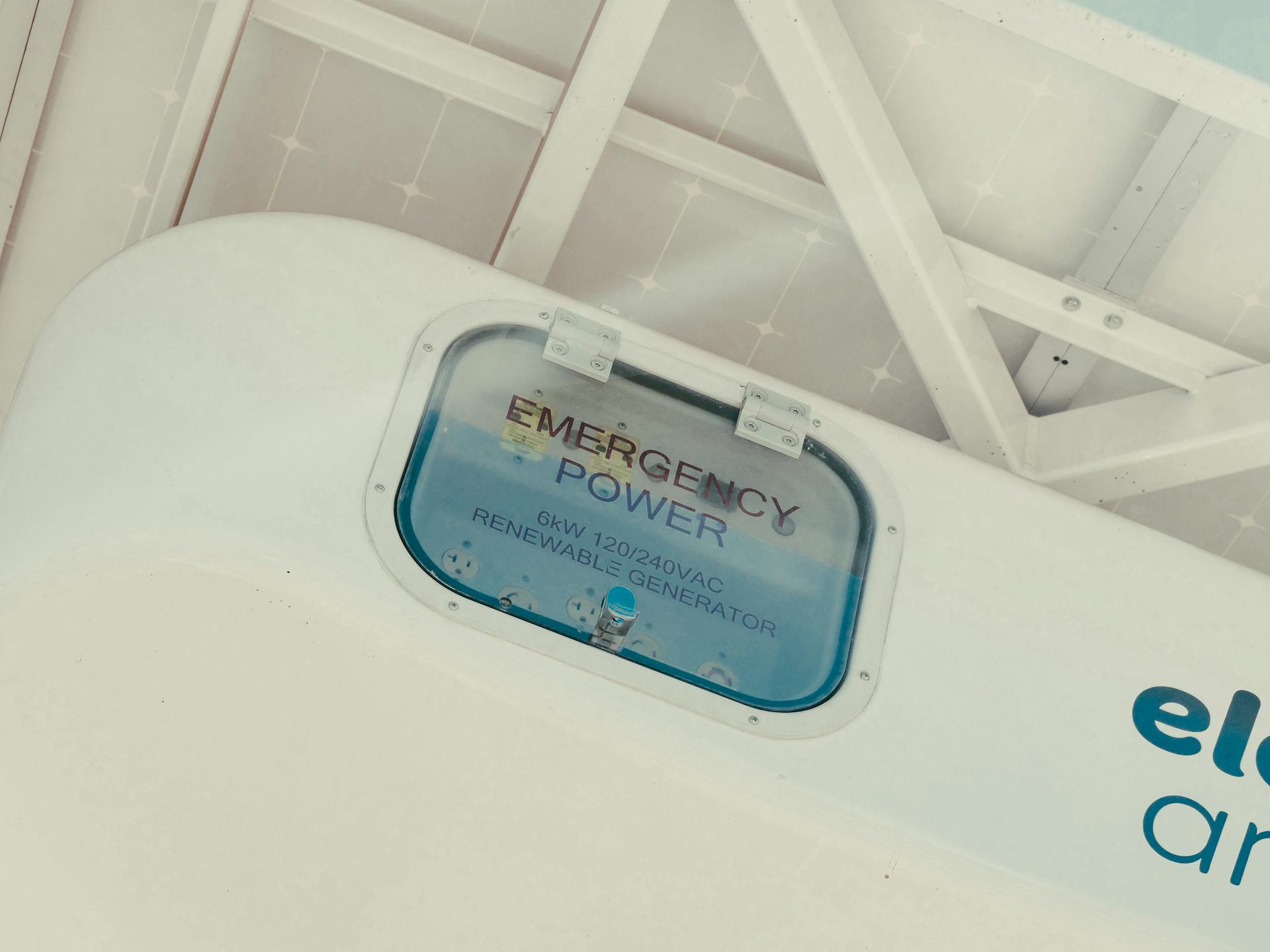

In emergency situations, gen sets can automatically switch to provide power, ensuring a stable supply. This is particularly important for critical applications like hospitals and data centers.

Gen sets are also suitable for remote locations or areas with unreliable grid power. They can be fueled by various types of fuel, such as diesel, natural gas, or propane.

Their ability to operate in a variety of environments and conditions makes gen sets a versatile solution for power generation.

For more insights, see: Gen Set Generator

Advantages and Benefits

Gen sets have come a long way in terms of efficiency and reliability. They offer a more efficient design, which translates to longer service life and fuel savings.

One of the key advantages of gen sets is their ability to provide ultra-low emissions. This is a significant benefit, especially in areas where air quality is a concern.

Expand your knowledge: What Year Is Gen V Set in

With multiple engine gensets, if one engine fails, the others can keep the train going, albeit at reduced speed. This ensures minimal disruption to services.

Gen sets also offer improved wheel to rail adhesion capability, which is essential for smooth and efficient train operation.

Here are some of the key benefits of gen sets:

- Reliability

- Fuel efficiency

- Scalable design

- Robust construction

- Automatic or manual paralleling

- Automatic loading control

- Local or remote operation

- Low emissions

Gen sets can be transported easily by land, sea, or air, housed within a standard ISO 12.2m (40 foot) container. This makes them ideal for rapid installation and commissioning globally.

APR Energy's gensets can be combined into scalable 5.5 MW blocks and can facilitate rapid installation up to 300 MW or more.

Types and Ratings

Gen set power ratings are defined by the industry standard ISO 8528, which classifies them into three main types: prime, continuous, and standby.

A generator's rating refers to its maximum power capability under specific conditions with regular maintenance. Generators rated for prime running power can be run 24/7 at near maximum load, usually around 80% max capability.

Here are the three main types of gen set power ratings:

- Prime Running Power (PRP) rating: Run 24/7 at near maximum load, up to 10% over rated output in rare overload situations.

- Continuous Operating Power (COP) rating: Run for an unlimited number of hours per year, but not as close to max capability as prime power, and never overloaded.

- Emergency Standby Power (ESP) rating: Run for no more than 200 hours per year at an average load of 80% their rated maximum output.

Prime vs. Standby vs. Continuous Ratings

Prime power generators are the best choice for applications that need a reliable source of primary power, especially when variable loads or overload situations might be present.

A prime power generator can be run 24/7 at near maximum load, usually around 80% of its maximum capability.

They can even handle loads of 10% over their rated output for short periods, as long as it's not overloaded for more than 1 hour in a 12-hour span, or 500 hours per year.

In contrast, standby generators should only be used in true emergency situations and never in parallel with utility lines.

Standby generators should be run for no more than 200 hours per year at an average load of 80% their rated maximum output.

Here's a quick comparison of the three types of generator ratings:

- Prime Power (PRP): Run 24/7 at near maximum load, can handle short overloads.

- Continuous Operating Power (COP): Run for unlimited hours per year, but at 70% of maximum rating on average.

- Emergency Standby Power (ESP): Run for no more than 200 hours per year in emergency situations only.

Diesel Portfolio

The Diesel Portfolio is a range of diesel engines offered by Mercedes-Benz.

For more insights, see: Quiet Diesel Generators

Mercedes-Benz offers a variety of diesel engines, including the OM 654 and OM 656 series.

These engines are designed to provide excellent fuel efficiency and performance.

The OM 654 engine is a 2.0-liter inline-4 cylinder diesel engine that produces up to 240 horsepower.

It's available in several models, including the E-Class and the C-Class.

The OM 656 engine is a 2.9-liter inline-6 cylinder diesel engine that produces up to 340 horsepower.

It's designed for heavy-duty applications and is available in the X-Class and the S-Class.

Readers also liked: Generac Generator Engine Manufacturer

Specifications and Maintenance

Prime power generators can be run close to their nameplate rating on a continual basis, but it's best to average about 80% of the maximum capacity to prevent premature wear.

You can run prime power generators continuously, but keep an eye on how often you run them in an overload situation. To be safe, try not to run them over capacity more than 500 hours in a year.

Intriguing read: How to Run Ac off Generator

Regular maintenance is crucial to preventing downtime. You should work with your generator distributor to develop a maintenance plan that fits your application, especially if you're subject to humidity, salinity, or extreme temperatures.

Solutions Specifications

A genset's enclosure is usually made of steel, stainless steel, or aluminum, and is designed to withstand corrosion and manage engine cooling effectively.

The baseframe of a genset often contains an anti-vibration system to minimize noise and ensure a smooth operation.

You'll also find a control panel and an automatic transfer switch in a genset, which allows for easy switching between the main source and an auxiliary one in case of an energy need.

The control panel is a crucial element in a genset, providing a centralized location for monitoring and managing the power generation system.

Superior transient performance is a key feature of some gensets, making them suitable for applications that require rapid changes in power output.

A mature and reliable design is also a notable characteristic of some gensets, ensuring a long and trouble-free operation.

Run Time and Maintenance

Prime power generators are designed to be run continuously, but it's essential to keep an eye on how often you run your generator in an overload situation.

There is no limit on the number of hours a prime power generator can be run in a given year, but running it over capacity more than 500 hours in a year is not recommended.

Regular maintenance is crucial to preventing downtime, and the frequency of maintenance depends on your application and environment.

If you're subject to humidity, salinity, or extreme temperatures, you'll need to service your generator more regularly.

Preventative maintenance at regularly scheduled intervals is imperative to keeping your prime power generator in top shape.

Here are some key maintenance considerations:

- Maintain your generator at about 80% of its maximum capacity to prevent premature wear.

- Keep track of your generator's run time to avoid overloading it more than 500 hours in a year.

Fuel and Emissions

The APR Energy gas power module is a highly efficient choice, with installation and commission possible in as quickly as 30 days.

Natural gas-powered modules like the APR Energy gas power module provide highly reliable, fuel-efficient energy to support fast-track power with automatic loading control. This module can support a broad range of power generation applications for industrial and utility usages, even in extreme conditions and/or in remote locations.

The APR Energy gas power module is designed to perform optimally on low-pressure pipeline natural gas, with low emissions. It features a CAT(R) G3516C low-emission gas engine designed for a methane number range of 55-100.

Diesel gensets, on the other hand, come with compact four-stroke-cycle CAT(R) 3516B turbo-charged diesel engines. They also offer continuous power output of up to 1640 kW and an engine speed of 1800 RPM.

Suggestion: Perkins Engine Generator

Gas vs Diesel

Choosing between a gas and diesel generator for your power needs can be a daunting task. Efficiency is a key factor to consider, with diesel generators being the more fuel-efficient option. However, diesel engines have risen in price, making it essential to weigh the lifecycle savings of choosing diesel or gas.

Fluctuating fuel prices can also impact your decision. If diesel prices have skyrocketed, a gas generator might be the more attractive option. Conversely, if diesel prices are low, then diesel might be the better choice.

Additional reading: Duromax Tri Fuel Inverter Generator

The application of the generator is also crucial. In the oil and gas industry, gas generators are the best option due to the abundance of cheap natural gas. In other industries, diesel might be the better option depending on the price.

Here are some key differences between gas and diesel generators:

Sustainable Fuels

Sustainable fuels are a game-changer in the fight against climate change, reducing greenhouse gas emissions by up to 80% compared to traditional fossil fuels.

One of the most promising sustainable fuels is hydrogen, which can be produced from renewable energy sources like solar or wind power.

Tier 4 Considerations

As of 2016, all diesel generators serving as an application's prime source of power are now controlled by the EPA's Tier 4 regulations.

All new generators purchased must be Tier 4 certified to meet the standards.

Tier 4 regulations aim to reduce the emission of harmful pollutants, particularly nitrogen oxides (NOx) and particulate matter (PM), in the atmosphere.

Even load management applications are regulated by Tier 4, so it's essential to check if your application must comply with Tier 4 standards.

To find out if your application must comply with Tier 4 standards, you can check out a flowchart that's available.

Applications and Industries

Gen sets are incredibly versatile and can be used in a wide range of applications, from data centers and power plants to manufacturing plants and independent power stations.

Prime power generators, in particular, are often used as a site's primary source of continual power, and can also be used for on-grid applications to offset power provided by utility providers during times of peak usage.

Data centers and power plants often implement prime power generators as a way to reduce electricity usage in times of high demand, a practice called load management.

Load management involves an agreement between the utility provider and the end-user to reduce electricity usage when demand is high, and prime power generators can be used to make up the difference.

You can use your prime power generator for load management in two ways: peak shaving or base loading. Peak shaving involves using the generator to make up the difference when your application exceeds the threshold of power provided by the utility provider, while base loading involves running the generator at a fixed output and having the utility provider make up the difference if needed.

Some of the industries that trust gen sets for reliable power include healthcare, data centers, airports, and manufacturing plants, with a product portfolio that covers diesel generator sets up to 3,250 kWe (60 Hz).

Load Management Applications

Load management applications are a game-changer for high-usage applications like data centers and manufacturing plants. They help prevent power outages and costly downtime by offsetting load demand with a prime power generator.

Prime power generators can be used for load management in two ways: peak shaving and base loading. Peak shaving involves running the generator when your application exceeds a fixed amount of power provided by the utility provider.

The utility provider pays the end-user for providing additional power during peak usage times. This helps the provider manage peak usage and predict power needs across the grid.

Base loading setups involve running the generator at a fixed output, and the utility provider makes up the difference if needed. Both methods can be implemented to prevent outages and ensure adequate power is always available.

Here are some common load management applications:

- Data centers

- Manufacturing plants

- Airports

- Waste water treatment plants

- Independent power stations

These applications benefit from load management by using prime power generators to create power and prevent power outages. This also allows the utility provider to reallocate power and add other users to the grid without having to create more power.

Myanmar Utility Sector

Myanmar Utility Sector is a fascinating example of how genset services can make a significant impact on a country's energy infrastructure. APR Energy, a leading company in the field, played a crucial role in providing energy to Myanmar post-sanctions.

In 2012, the United States and multiple European Union nations lifted sanctions, opening up opportunities for foreign investment. This led to APR Energy signing a power generation agreement with Myanmar's government in 2014.

APR Energy's genset services were instrumental in addressing Myanmar's energy challenges. The company installed one of the country's largest thermal plants within 90 days, with 70 percent of the workers sourced locally. This achievement won a Top Plants 2015 award.

One of the key reasons Myanmar Electric Power Enterprise chose APR Energy for their genset services was their ability to rapidly design and deploy power plants on a large scale. This skill was essential in meeting the country's energy demands.

APR Energy's genset services also had a positive impact on the local community. The company employed local workers and provided valuable training, furthering the community's economic development.

Guatemalan Mining

APR Energy provided reliable power for the world's second-largest silver mine in Guatemala using diesel gensets. This was a critical project that required a scalable solution to meet the mine's needs.

The mine, Escobal, is located in a rural, mountainous region, which presented challenges for the project. APR Energy designed and installed a system to ensure uninterrupted power in a life-dependent situation.

To meet the mine's requirements, APR Energy initially provided 2-3 MW of power for construction. This was later scaled up to 15.5 MW of reliable electricity, which was crucial for miners working underground.

APR Energy maintained rigorous standards and trained workers in occupational health, safety, and environmental best practices.

Frequently Asked Questions

Is it gen set or genset?

The correct term is "genset," which is a shortened form of "generator set

Why is it called a gen set?

A genset is called a gen set because it's a combination of a motor and alternator set in a single base frame. The name "gen set" is a shortened form of "generator set", which accurately describes its primary function.

Featured Images: pexels.com